9

Falcon GTE -

Installation & Servicing

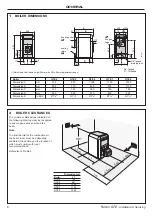

GENERAL

8

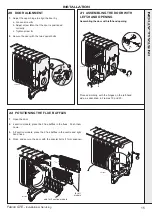

SYSTEM DESIGN

Minimum Water Flow

Design Flow Rates

The following table gives the flow rate required for each boiler

based on a design temperature difference of 11

o

C (20

o

F) at the

maximum rated output. For hydraulic resistance see General

Data table (page 2).

Minimum Flow Rates

It may be necessary to fit a shunt pump to ensure minimum flow

rates.

Boiler Size (no of sections)

4

5

6

7

8

Normal water flow rate

l/s

1.09

1.39

1.69

2.00

2.21

temperature difference 11

o

C (20

o

F)

g.p.m.

14.4

18.4

22.3

26.4

29.2

Minimum water flow rate

l/s

0.34

0.44

0.53

0.63

0.70

temperature difference 35

o

C (63

o

F)

g.p.m.

4.5

5.8

7.0

8.3

9.3

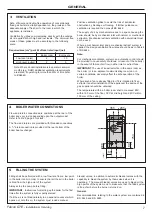

System Design

Recommendations relating to water system design are

contained in BS. 5410: Part 2, BS. 6798 and BS. 6880.

System design must allow for adequate internal circulation

within the boiler and sufficient heat release from the boiler

body during and immediately after burner firing. Heating and/

or hot water controls should be interlocked electrically with the

burner, to prevent firing when the system does not demand

heat.

Depending on system design it may be necessary to interrupt

electrical supply to the burner before any mixing valves are

completely closed to the boiler flow. This will dissipate residual

heat. Also a pump overrun of at least 5 minutes is required on

plant shutdown to avoid interference trip out of the overheat

thermostat. If system return temperature remains below 30

o

C

for most of the heating period some protection from

condensation is required.

Please contact Caradon Ideal Limited for further information.

The example assumes flow rate required through

the DHW storage cylinder is less than that required

by the boiler. A combined shunt/DHW primary pump siz ed

on the minimum flow to be required MUST be fitted.

Provided adequate heat dissipation can be achieved at all

times the combined pump only may run on during the

overrun period - allowing the heating pump to switch off.

In order to achieve adequate heat dissipation into the DHW

storage cylinder, the diverter valve MUST always open

during the overrun period of 5 minutes.

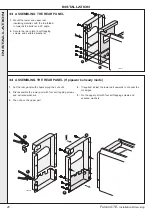

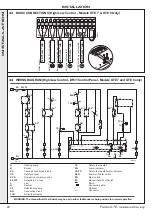

Example A

- Heating only utilizing a mixing valv e

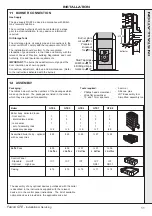

Example B

- Combined domestic hot w at er and heating using a mixing valve

Example C

- Combined domestic hot wat er using a divert er valve, and heating using a mixing valve

Shunt

pump

Mixing valve

Heating pump

Bypass

Load

A shunt pump sized on the minimum flow rate required

MUST be fitted. Both heating and shunt pumps MUST run

on during the overrun period of 5 minutes.

The mixing valve MUST NOT be capable of complete

closure to bypass, in order that residual heat can be

dissipated.

DHW

storage

DHW Primary pump

Shunt

pump

Heating

pump

Bypass

Mixing valve

A shunt pump sized on the minimum flow rate required

MUST be fitted. Provided adequate heat dissipation can be

achieved at all times the shunt and DHW primary pumps

only may run on during the overrun period of 5 mins -

allowing the heating pump to be switched off. This

example assumes the DHW primary pump flow rate

required is less than that required for the shunt pump.

Load

Diverting

valve

Combined shunt and

DHW primary pump

Shunt

bypass

Bypass

Bypass

Heating pump

Load

Mixing valve

DHW

storage

Notes:

Minimum static head requirements with limit thermostat set at 100ºC (212ºF) : 2.5m.

The examples illustrated are intended as a general guide only.

Caradon Ideal Limited

will be pleased to advise on specific applications.

Design and minimum flow rate tables are shown in this leaflet.

FAL5816

Содержание Falcon GTE 4

Страница 30: ...30 Falcon GTE Installation Servicing NOTES...

Страница 31: ...31 Falcon GTE Installation Servicing NOTES...