EVOMAX - MULTILINE FLUE KITS

9

COMMISSIONING

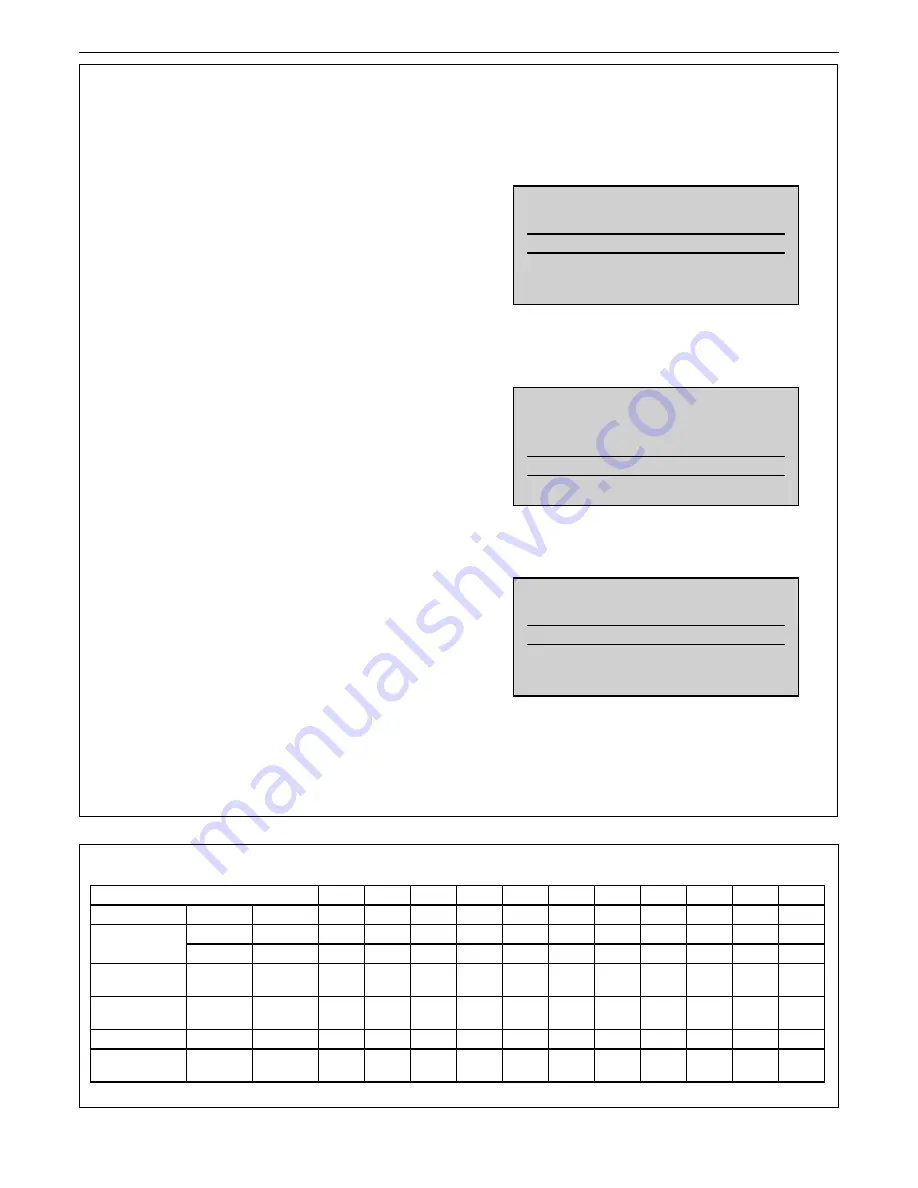

4.1 EVOMAX CASCADE FLUE SYSTEM – MINIMUM RATE BOILER SETTINGS & DATA

Evomax Boiler Model

30

30P

40

40P

60

60P

80

80P

100

120

150

Fan Speed

rpm

1980

2100

2400

2340

1800

1800

2340

2220

2280

1860

1800

Input

net

kW

7.6

7.6

10.1

10.1

15.2

15.2

20.5

20.5

25.6

30.7

38.4

gross

kW

8.4

8.3

11.2

11.0

16.9

16.5

22.7

22.3

28.4

34.1

42.6

Output

non-condensing

kW

7.5

7.5

10

10

15.0

15.0

20

20

25.0

30.0

37.5

Output

condensing

kW

8.0

7.8

10.7

10.4

16.0

15.7

21.6

21.2

27.0

32.4

40.5

Flue CO

2

± 0.5

%

9.0

10.6

9.0

10.6

9.0

10.6

9.0

10.6

9.0

9.0

9.0

NOx

(weighted)

Cat 5

mg/kWh

33

82

41

84

35

84

42

68

43.5

41

40.5

4.0 COMMISSIONING

To accommodate the flue pressure generated by the

connection of multiple boilers to a common flue, the minimum

rate (equivalent to minimum fan speed) of each Evomax

appliance operating on the Multiline cascade system is

increased to offset the maximum back-pressure created.

Table 4.1 shows the revised performance of each Evomax

model where it differs from standard standalone operation as

shown in the Evomax Installation & Servicing instructions.

To convert Evomax operation with the Multiline flue as

described, the change is made by accessing the operating

parameters on the Evomax user interface control panel

following the procedure below. This change must be made to

each Evomax operating on the Multiline cascade system.

Procedure for selecting Multiline cascade flue operation

on Evomax user interface control panel.

1.0

Press SELECT and then hold + and – buttons down

together for more then 5 seconds, the following screen

will be displayed.

2.0

Rotate the KNOB clockwise and scroll downwards

towards the end of the list until the following screen is

displayed.

3.0

Press SELECT and the following screen will be

displayed.

4.0

Press + or - to highlight ‘Multiline Flue’ and then press

ENTER to store.

5.0

Rotate the KNOB clockwise until Normal Operation

is highlighted again and press SELECT to return to

normal operation.

INSTALLER MODE

NORMAL OPERATION

SET FLOW TEMP’

SET DHW TEMP’

INSTALLER MODE

FLAME/LPG RELAY

FLUE SETTING

NORMAL OPERATION

INSTALLER MODE

STANDARD FLUE

MULTILINE FLUE

Содержание Evomax 30

Страница 14: ...NOTES 14 EVOMAX MULTILINE FLUE KITS...

Страница 15: ...NOTES 15 EVOMAX MULTILINE FLUE KITS...