Note

.

Natural gas consumption is calculated using a calorific value of

37.8MJ/m

3

(1038Btu/ft

3

) gross or 34 MJ/m

3

(910 Btu/ft

3

) nett at

15

o

C and 1013.25 mbar.

a

. For l/s divide the gross heat input (kW) by the gross C.V. of the

gas (MJ/m

3

)

b. For ft/h

3

divide the gross heat input (Btu/h) by the gross C.V. of

the gas (Btu/ft

3

).

c. For m

3

/h multiply l/s by 3.6.

d. 1kW = 3412 BTU/hr.

e. 1m

3

= 35.3ft

3

f. 1mg/kWh (NOx) = 0.568 ppm DAF (natural gas).

Propane gas consumption is calculated using a calorific value of

95.7 MJ/m

3

(2500 Btu/ft.

3

) gross or 88.0 MJ/m

3

(2300 Btu/ft.

3

) net

at 15

o

C and 1013.25 mbar.

To obtain the fuel consumption in liquid form divide the above

figures by 270.

** The value is used in the UK Government’s Standard Assessment Procedure (SAP) for energy ratings of dwellings. The test data from which it has been calculated have

been certified by a notified body.

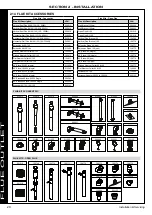

Table 2 General Data

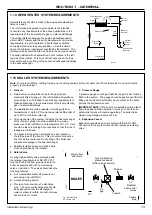

HEALTH & SAFETY DOCUMENT NO. 635

The electricity at work regulations, 1989

. The manufacturer’s

notes must NOT be taken, in any way, as overriding statutory

obligations.

IMPORTANT

. These appliances are CE certified for safety

and performance. It is, therefore, important that no external

control devices, e.g. flue dampers, economisers etc., are

directly connected to these appliances unless covered by

these Installation and Servicing Instructions or as otherwise

recommended by Ideal Boilers in writing. If in doubt please

enquire.

Any direct connection of a control device not approved by Ideal

Boilers could invalidate the certification and the normal appliance

warranty. It could also infringe the Gas Safety Regulations and

the above regulations.

Model

30

30P

40

40P

60

60P

80

80P

100

100P

120

120P

150

Boiler Output

(non-condensing)

Mean 70

°

C

Max

kW

30

30

40

40

60

60

80

80

100

100

120

120

150

Min

kW

6

6

8

8

12

12

16

16

20

20

24

24

30

Boiler Output

(condensing)

Mean 40

°

C

Max

kW

31.5

30.9

42

41.2

63.5

62.1

84.4

82.6

103.9

101.7

124.7

123.3

158

Min

kW

6.5

6.4

8.5

8.3

12.7

12.4

17.2

16.8

21.6

21.3

26

25.7

32.5

Boiler Input

Max Rate

Nett

kW

30.4

30.4

40.5

40.5

60.8

60.7

82

81.9

102.4

102.4

122.9

122.9

153.7

Gross

kW

33.7

33

44.9

44

67.4

66

90.9

88.9

113.6

111.2

136.4

133.4

170.5

Boiler Input

Min Rate

Nett

kW

6.1

6.1

8.1

8.1

12.2

12

16.4

16.2

20.5

20.4

24.6

24.5

30.7

Gross

kW

6.7

6.6

9

8.8

13.5

13.1

18.2

17.5

22.7

22.2

27.3

26.7

34.1

Gas Rate

Max Rate

m

3

/hr

3.2

1.26

4.3

1.69

6.4

2.53

8.7

3.41

10.8

4.35

13

5.23

16.2

Flue Gas Flow Rate

Max Rate

m

3

/hr

41.3

44.09

54.05

61.68

80.65

88.66

110.1

121.57

140.5

153.6

173.33

183.81

210.7

CO

2

(±0.5%) *

Max Rate

%

9.76

10.9

10.2

11.2

9.4

11.4

9.3

11.4

9.4

10.8

9.62

11.2

9.44

Min Rate

%

8.56

10.3

8.6

9.7

8.6

10.2

8.7

10.8

8.6

10.1

8.98

10.1

8.51

DB

55.2

55.2

57.7

57.7

59

59

59.9

59.9

62

62

62

62

59

NO

x

(gross)

weighted

mg/kWh

34.1

52.3

33.2

64.4

35.2

67.7

34.9

63.2

34.8

65.3

33.9

41.6

35.7

Efficiency

Seasonal

%

96.7

97.2

96.2

96.7

96.4

96.9

97.2

97.7

96.7

96.7

96.6

96.6

96.7

**SEDBUK 2009

%

89.6

90.6

89.3

90.3

89.4

90.5

n/a

n/a

n/a

n/a

n/a

n/a

n/a

Max. operating temp sealed sys.

ºC

85

Max. operating temp open vented sys.

ºC

82

*CO

2

measurements taken using controlled reference natural gas. Readings on mains gas quality may vary

Model

30

30P

40

40P

60

60P

80

80P

100

100P

120

120P

150

Gas Supply

2H – G20 – 20mbar / 3P - G31 - 37mbar

Gas Supply Connection

G ¾

Flow Connection

G 1¼

Return Connection

G1¼

Max Pressure (sealed sys)

Bar (psi)

6.0 (87)

Maximum Static Head

m

61.0

Electricity Supply

230V - 50Hz

Fuse Rating

A

4.0

Power Consumption

W

81

138

82

149

187

243

240

IP Rating

IPX4D

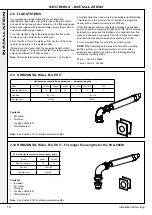

Nominal flue dia - Concent.

80/125

100/150

Condensate Drain

mm

25

Water Content

L

3.0

5.0

7.0

9.2

Packaged

Kg

53.5

63.5

80

88

Unpackaged (dry weight)

Kg

47.5

57.5

73

81

Table 1 Performance Data (Natural Gas & Propane (P))

6

Installation & Servicing

SECTION 1 - GENERAL

Содержание EVOMAX 2 30

Страница 4: ...4 Installation Servicing...

Страница 75: ...75 Installation Servicing NOTES...

Страница 76: ...76 Installation Servicing NOTES...

Страница 77: ...77 Installation Servicing NOTES...

Страница 78: ...78 Installation Servicing NOTES...

Страница 79: ...79 Installation Servicing NOTES...