34

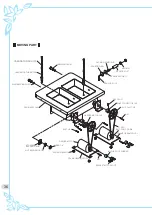

Refrigerant circuit

Charging Refrigerant

L.P

H.P

N2

Vacuum

Pump

R404A

Scales

MANIFOLD

E.P.R

Service Port

1

2

3

Mix tank

Capillary

Dryer

Suction pipe

For keeping in

the refrigerator

Automatic Expansion Valve

Freezer

Condenser

Compressor

Fan

H.P S/W

Discharge pipe

Thermostat

F

il

te

r

D

rye

r

Moter

Thermostat

Comperssor

For keeping

in the freeze

Suction pipe

①

Leak Test

When the refrigeration system is opened to repair or service the refrigerant system,

conduct leak test before vacuum work, at the expanded and welded tube joints.

1) Connect the manifold gauge to the low-pressure service port, and connect nitrogen

gas tank to the manifold gauge

2) When the manifold gauge indicates 300 PSIG, close the valve.

3) Perform leak test with the entire refrigerant system.

4) If there is no leakage, close the manifold and disconnect the nitrogen gas tank.

②

Vacuum

Remove the moisture and air from the refrigerant system before charging refrigerant.

1) Connect vacuum pump with the manifold gauge, and start the vacuum pump.

2) The vacuum time shall be at least 30 minutes and the manifold pressure shall be

maintained at 740~750mmHg.

3) When full vacuum state is reached, close the manifold gauge and disconnect the

vacuum pump.

③

Charging Refrigerant

1) Connect refrigerant container to the manifold.

2) Open the refrigerant container valve slightly and purge the air from the manifold hose.

3) Measure the gross weight of the refrigerant container using a balance.

4) Place the refrigerant container upside down, with the valve at the bottom. Wait until

the refrigerant stabilizes. Open the valve to charge the refrigerant.

5) When the refrigerant has been fully charged, disconnect the manifold.

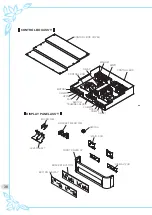

Содержание ISI-143S

Страница 32: ...32 Wiring diagram ...

Страница 37: ...37 Part List DASHER ASS Y ...

Страница 40: ...3240215 03 Online Internet Service http www icetro com ...