28

Removal and Replacement of Condenser'

E. Removal and Replacement of Condenser'

1. Always install a new drier every time the sealed refrigeration system is opened.

2. Do not replace the dried until after all other repair or replacement has been made.

Install the new drier with the arrow on the drier in th

3. When brazing, protect the drier and 4-way valve by using a wet cloth to provent the

drier and 4-way valve from overheating, Do not allow the drier to exceed 250

℉

(121

℃

)

1) Turn off the power of ELCB.

2) Open the side door.

3) Recover the refrigerant using an adequate vessel.

5) Remove the inlet and the outlet from the condenser.

6) Open the back panel cover.

7) Remove the harness from the fan motor.

8) Remove the four screws from the fan motor assembly.

ser

(total of 4 screws on the left and the right).

10) Replace the condenser with a new one.

enser

(total of 4 screws on the left and the right).

12) Replace the drier with a new one.

13) While purging with nitrogen gas at pressure of 3~4 psig, braze the copper connections

such as the condenser inlet and outlet.

14) Inject nitrogen at pressure of 140 psig and check for leaks with electric leak detector

or soap water.

15) Vacuum the system and inject the refrigerant.

16) Tighten the four screws from the fan motor assembly.

17) Connect the harness to the fan motor.

18) Tighten the screws on the back panel cover.

19) Close the side door.

20) Turn on the power of ELCB.

WARING

Содержание ISI-143S

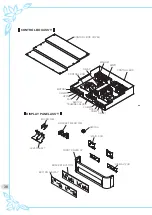

Страница 32: ...32 Wiring diagram ...

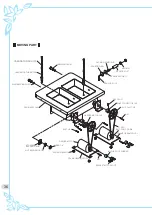

Страница 37: ...37 Part List DASHER ASS Y ...

Страница 40: ...3240215 03 Online Internet Service http www icetro com ...