20

By running the ice maker, i.e. by putting the unit

under power, starts the automatic and conti-

nuous icemaking process which would not stop

until the ice storage bin gets filled-up to the

level of the control “eyes” located on the ice

chute. As the ice level raises to interrupt the

light beam running between the two infrared

leds, the unit stops after six seconds (compres-

sor first and 3' later the gear reducer), with the

simulteneous glowing of the

YELLOW LED

signalling the

“Full Bin”

situation.

As some ice gets scooped out from the storage

bin, the light beam between the two sensors

resumes (fast blinking of YELLOW LED) and six

seconds later the ice machine restarts the ice

making process - going always through the 3'

stand by - and the YELLOW LED goes off.

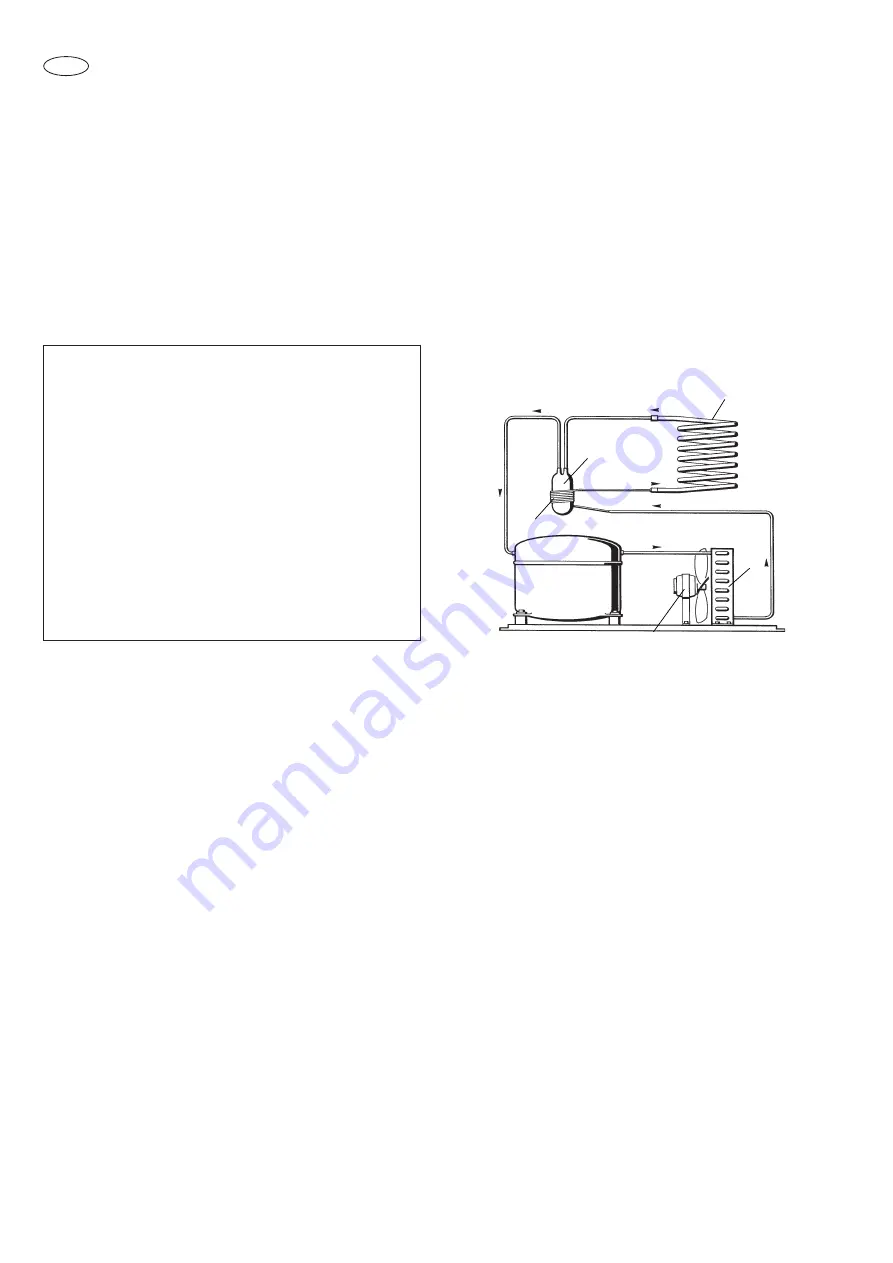

REFRIGERANT CIRCUIT

The hot gas refrigerant discharged out from the

compressor reaches the condenser where,

being cooled down, condenses into liquid.

Flowing into the liquid line it passes through the

drier filter, then it goes all theway throughtheca-

pillary tubewhere it looses some of its pressure

so that its pressure and temperature are lowe-

red.

Next, the refrigerant enters into the evaporator

coil wrapped around the freezer inner tube.

The water being constantly fed at the interior of

thefreezer inner tube,exchange heat with the

refrigerant circulating into the evaporator coil,

this cause the refrigerant to boil-off and evapo-

rate, there by it changes from liquid into vapor.

The vapor refrigerant then passes through the

suction accumulator and through the suction line

where the refrigerant exchanges heatwith the

one flowing into the capillary tube (warmer) befo-

rebeingsuckedinto thecompressor to be recircu-

lated.

The refrigerant head pressure is kept between

two pre-set values (8¸9 bar -110¸125 psig on

F120 and 17¸18 bar - 240¸250 psig on F200,

SF300, SF500 and SFN1000) by the condenser

temperature sensorwhich has its probe loca-

tedwithin the condenser fins - in air cooled ver-

sions.

This condenser temperature sensor, when sen-

ses a rising of the condenser temperature

beyond thepre-fixedlimit,changesits electrical

resistance and send a low voltage power flow to

the

MICROPROCESSOR

of the P.C. Board

which energizes,

through a

TRIAC

, the Fan Motor in ON-OFF

mode.

On the water cooled versions, the refrigerant

head pressure is kept at the constant value of 8.5

bar 8.5 bar (120 psig) on F200 and of 17 bar

(240 psig) on F200, SF300, SF500 and SFN1000

by themetered amount ofwater passing through

the condenserwhich is regulated by the action of

theWater Regulating Valve that has its capillary

tube connected to the liquid refrigerant line. As

pressure increases, the water regulating valve

opens to increase the flow of cooling water to

the condenser.

NOTE.

The interruption of the light beam

between the two light sensors is immediately

signalled by the blinking of the

BIN FULL

YELLOW LED

located on the front of the

P.C. Board.

After about

6" of steady interruption

of the

light beam the unit stops and the

“Full Bin”

YELLOW LED

glows steady.

The six seconds of delay prevent the unit

from stopping for any undue reason like the

momentarily interruption of the light beam

caused by the flakes that slides along the ice

spout before dropping into the bin.

ACCUMULATOR

CAPILLARY TUBE

DISCHARGE LINE

EVAPORATOR

FAN MOTOR

COMPRESSOR

C

O

N

D

E

N

S

E

R

S

U

C

TI

O

N

L

IN

E

Содержание F 125C

Страница 17: ...15...

Страница 35: ...35 WIRING DIAGRAM F 80C Air cooled 220 240 50 1...

Страница 36: ...36 WIRING DIAGRAM F 80C Water cooled 220 240 50 1...

Страница 37: ...37 WIRING DIAGRAM F 125C Air water cooled 220 240 50 1...

Страница 38: ...38 WIRING DIAGRAM F 120 F 200 Air water cooled 220 240 50 1...

Страница 39: ...39 WIRING DIAGRAM SF 300 SF 500 Air water cooled 220 240 50 1...

Страница 40: ...40 WIRING DIAGRAM SF 500 Air water cooled 400 50 3...

Страница 41: ...41 WIRING DIAGRAM SFN 1000 Air water cooled 400 50 3...

Страница 47: ......