ibidi Pump System

Switching between State 1 and State 2 generates a continuous unidirectional flow of medium through

the slide. Sterility is maintained by the use of air filters on top of the reservoirs. Note, that it is

beneficial to supply CO

2

-rich air to the medium in order to properly buffer it. Therefore, the rear

pump port should be connected to the incubator.

If the system is run with negative pressure, the principle remains the same, however, the flow direc-

tion is reversed (right to left).

8.2

Positive Versus Negative Air Pressure

The ibidi Pump System can be set up using positive or negative pressure. Although, in most cases,

best results are achieved using positive pressure, there are instances in which negative pressure is

appropriate for an experiment. The pros and cons of positive and negative pressure are discussed in

this section.

Positive Air Pressure

When using positive air pressure, the front port of the pump pushes out pressurized air. The ambient

air is drawn into the ibidi Pump at the rear port. This means, that the air applied to the Fluidic Unit(s)

is not enriched in CO

2

. For an optimal CO

2

supply, a tubing is connected to the rear port and leads

into the incubator, to such in the CO

2

-enriched incubator atmosphere. When using this setup, make

sure to use the drying bottle to prevent condensation in the pump from the warm and humid air

(Figure

When using positive air pressure, an overpressure is created within the system. As a result, air (and

also medium) is more likely to be pressed out of the system rather than drawn in. Therefore, the

system is less vulnerable to contamination or gas bubble formation. Additionally, the air supply to

the Fluidic Unit is dry, which will keep the sterility filters on the Perfusion Sets dry, ensuring optimal

performance. However, the setup needs additional tubing compared to the negative pressure setup.

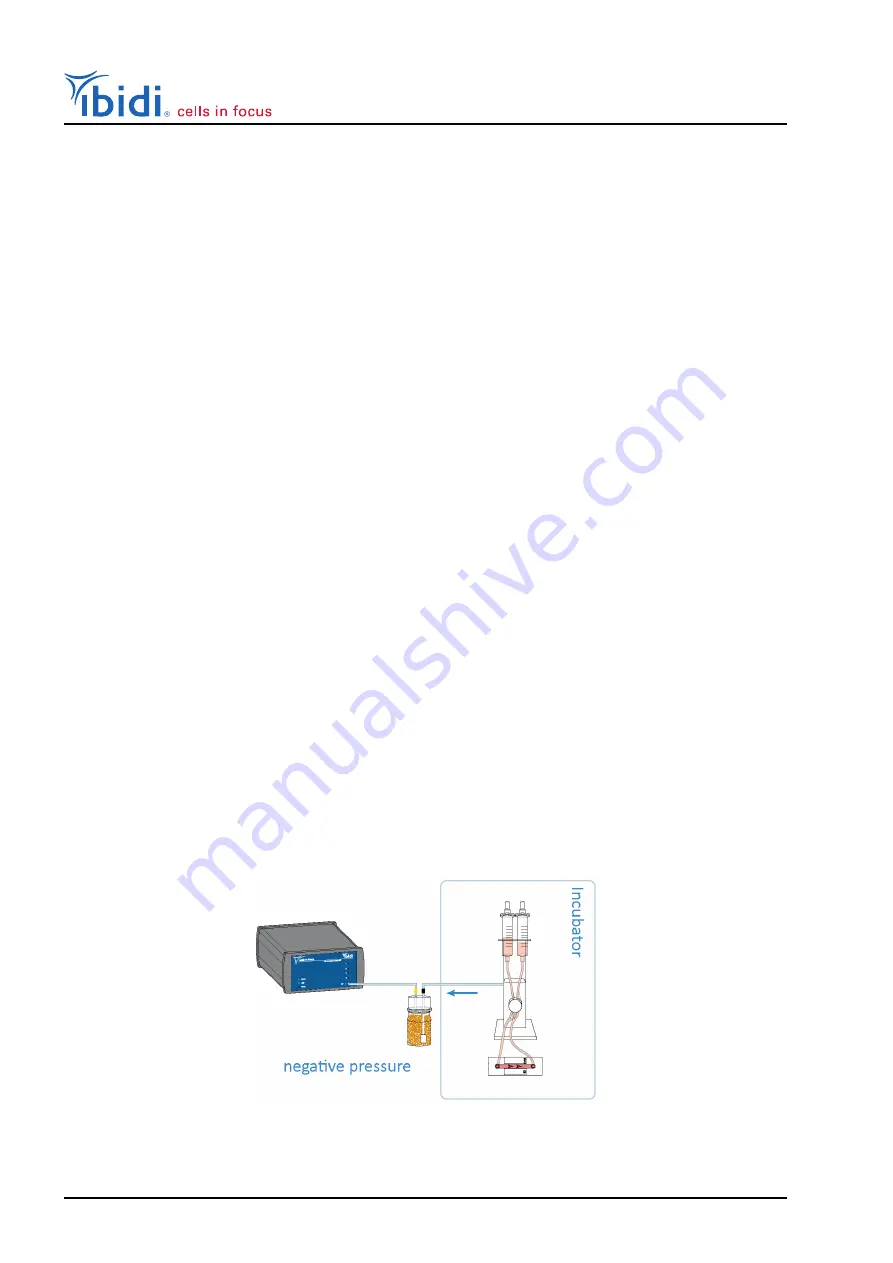

Negative Air Pressure

When using negative air pressure, the pump aspirates air through the Fluidic Unit directly from the

incubator. Thus, it is humid and rich in CO

2

. The drying bottle must be integrated between the

Fluidic Unit and the pump to protect the pump from condensation (Figure

To apply negative air pressure, use negative values to indicate the air pressure in the PumpControl

software.

Figure 49: Setup of the drying bottle with negative pressure.

Version 2.6 (May 12, 2022)

62

Instruction Manual