19

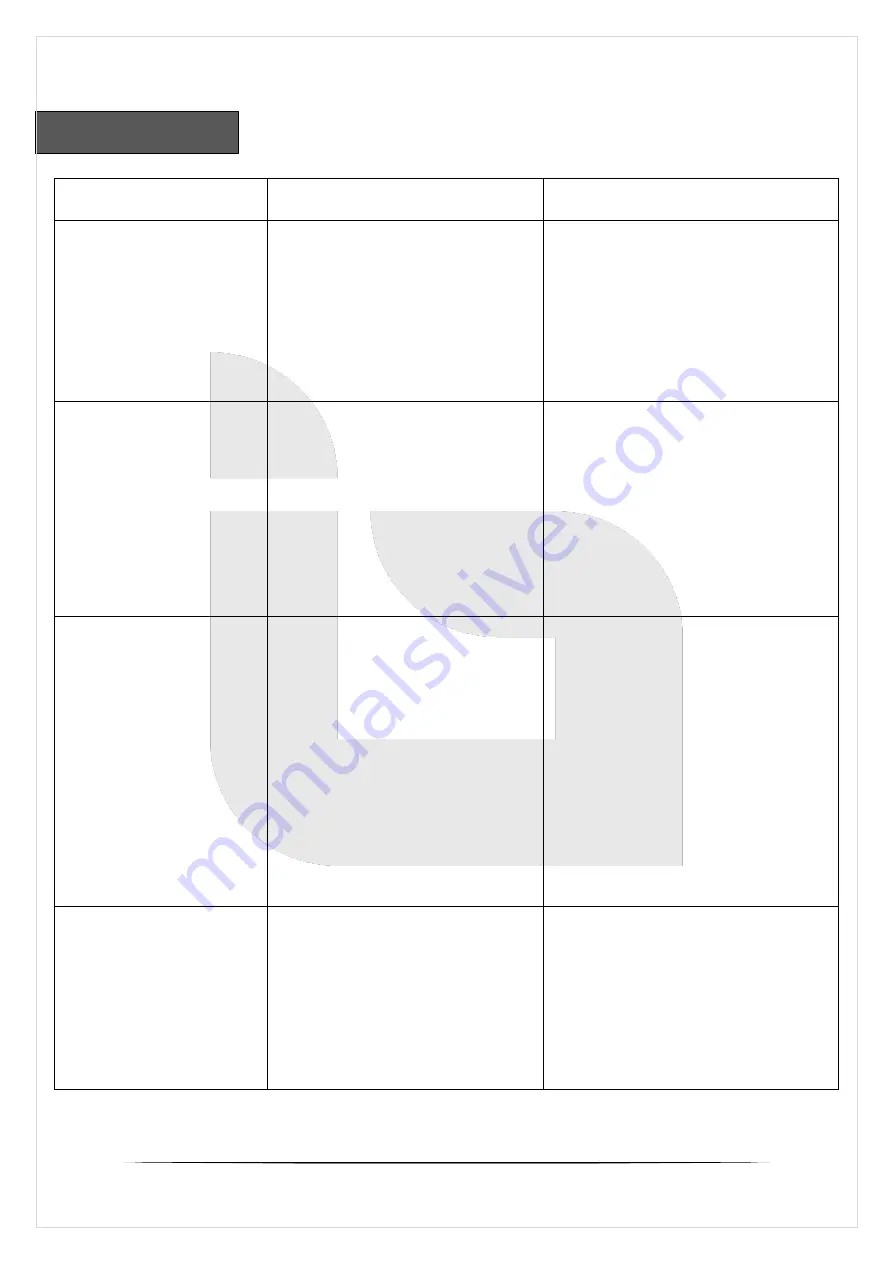

Problem

Possible Cause

Solution

1.

Wire feeds,

but no arc

1.1 Poor grounding/

ground connection.

1.2 Trigger not pulled

while wire is in

contact with work.

1.1 Check connection/

Tighten ground cable

.

1.2

Press the trigger

while in contact

with the workpiece.

2. Arc works, but

not feeding

wire

2.1 Insufficient or

excessive pressure

on the drive roller.

2.2 Wire reel/spool is

empty.

2.1 Adjust the drive

pressure.

(See page no.13)

2.2

Check if wire is in

place and replace if

necessary.

3.

No arc or wire

feed.

3.1 Exceeded duty

cycle (>60%);

[Thermal protector

engaged]

3.2 Insufficient air

flow/ Overheat.

3.3 Circuit breaker

has been tripped.

3.1

Allow it to cool at

least 10 minutes

with machine ON.

3.2

Check the vents on all

sides of the machine

for any obstacles.

3.3

Make sure circuit

breaker is reset.

4. Poor quality

welds.

4.1 Gun moved over

workpiece too

quickly/too slowly

.

4.2 Insufficient

amperage.

4.1 Move the gun in a

standard manner.

4.2 Enhance the welding

current.

MAG WELDING

IBL M200-105

Содержание IBL M200-105

Страница 1: ...FLUX CORED MAG MMA IBL M200 105 WELDING MACHINE OPERATORS MANUAL ...

Страница 2: ...1 ...