ESD GROUNDING

(cont)

NOTE:

If benches are moved to another location, the ground bolts in

the worksurfaces should be re-tested. Refer to EOS/ESD document S4.1-

1990 Worksurfaces-Resistive Characterization for proper testing

methods. If ground has been disturbed between the bolt and the static

dissipative laminate, DO NOT OVER TIGHTEN ground bolts to achieve

proper ground. If ground cannot be re-established, loosen nuts

underneath bolt and remove ground bolt from hole. It may be necessary

to hold the threads of the bolt with a small screwdriver in order to

stabilize it to remove the nuts. Paint a thin layer of CONDUCTIVE

ADHESIVE or CONDUCTIVE PAINT on the small "ledge" of conductive

laminate where the bolt head rests and underneath THE HEAD of the

ground bolt. Set bolt back into the hole while liquid is still wet and

test ground immediately. At the point ground is reestablished, let the

liquid dry before reattaching the ground wire.

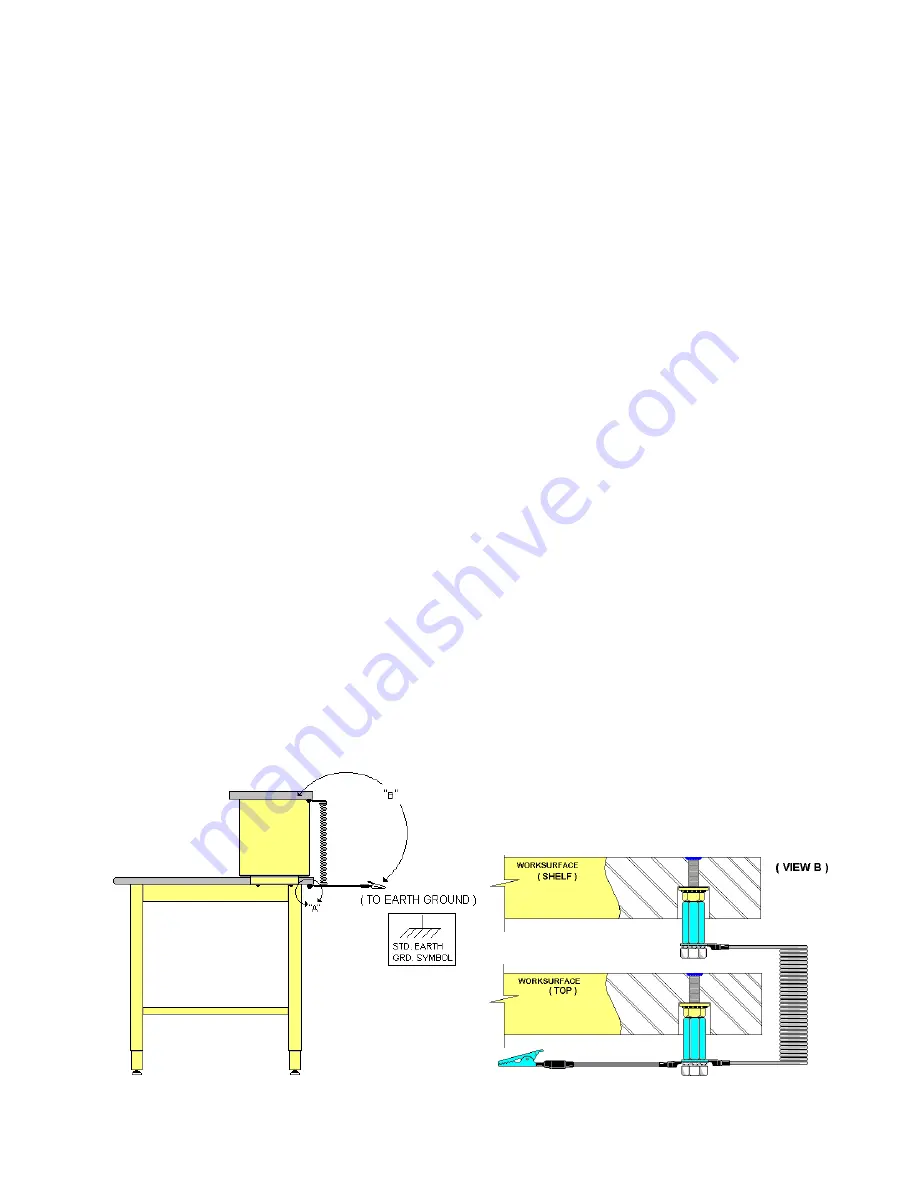

GROUNDING OF ESD SHELVES:

Coiled ground cord has an eyelet at both ends. Slip one eyelet end over

the 1/4-20x1/2" Hex Head Bolt in the ESD Grounding Kit for the

worksurface (Hardware Kit #HWR014) before screwing the bolt into the

1/4-20x7/8" nut. (See diagram on previous page). Slip the other eyelet end

over the 1/4-20x1/2" Hex Head Bolt in the ESD Grounding Kit for the

shelf (Hardware Kit #HWR122) and attach to one of the ground bolts

under the shelf as shown in the diagram on the previous page.

CLEANING:

Hard surface laminate is designed to resist abrasion,

scuffing, scorching, hot solder, flux and most solvents. Intense

exposure, such as from a hot soldering iron is not recommended. The

surface cleans easily with a damp cloth and soapy water. A mild chemical

cleaner with no abrasive can be used for stubborn spots. Remove glue

and grease with a non flammable adhesive solvent such as 3M Scotch-

Grip Solvent No. 4-F. Stains can be removed with a two minute exposure

to a 5% hypo chloride bleach solution, followed by a clean water rinse.

Never wax surface, as waxes may insulate.

11