that the packages are truly spaced properly. Attempting to sort packages with too

little gap between them can cause jams.

Note: The minimum gap necessary for sorting a package is a function of the width

of the package. The charts below should be used in checking for proper gap.

* W = Maximum Package Width

Note: When sorting to both

sides, the minimum gap from the

above charts must be increased

by 3 in.

Jam/Confirmation Photo-eye

—Photo-eyes mounted on each take-away spur of

the sorter, as close to the sorter as possible. These eyes perform two functions:

1. Detect a product jam at the sorter “exit point.” If a package blocks this photo-eye

for a longer time than it would take for the package to travel past the photo-eye

normally, this indicated that the package is jammed. The sorter should be stopped

and the jam cleared before restarting the sorter.

2. Divert confirmation. If a divert signal is given to a particular divert point, and no

package is detected by the associated jam/confirmation photo-eye, an error has

occurred. The sorter should be stopped and the error found and corrected before

restarting the sorter.

Full Line Photo-eye

—Photo-eyes mounted on each divert lane from the sorter,

near the infeed end of that lane. These eyes are used to signal the system controls

that a particular divert lane is full. The controls should then send any further

packages assigned to that lane to the recirculation line until the full line photo-eye

on that lane no longer indicates the full condition.

Recommended Controls Procedures

The following are recommendations to assist in the design and installation of

system controls that are interfacing with ProSort sorters.

• Do not place 24VDC control wires in the same wireway with AC power wires,

especially if the AC power exceeds 240 volts. “Noise” produced in the control wires

by the power wires may produce undesirable effects.

• Do not use optional “standard prox output” of the smart prox as a substitute for

an encoder. The five inch spacing between divert shoes does not provide enough

tracking resolution to accurately sort packages.

• Do not use manual override operator of the solenoid air valve to operate a divert

switch while the sorter is running. Doing so bypasses the switch timing controls and

may cause switch damage or a sorter crash.

• Do treat the tripping of any safety switch, motor overload, or low air pressure

signal as an emergency stop. Inspect the safety switch and other parts of the

sorter to be sure everything is in good working order before starting or restarting

the sorter.

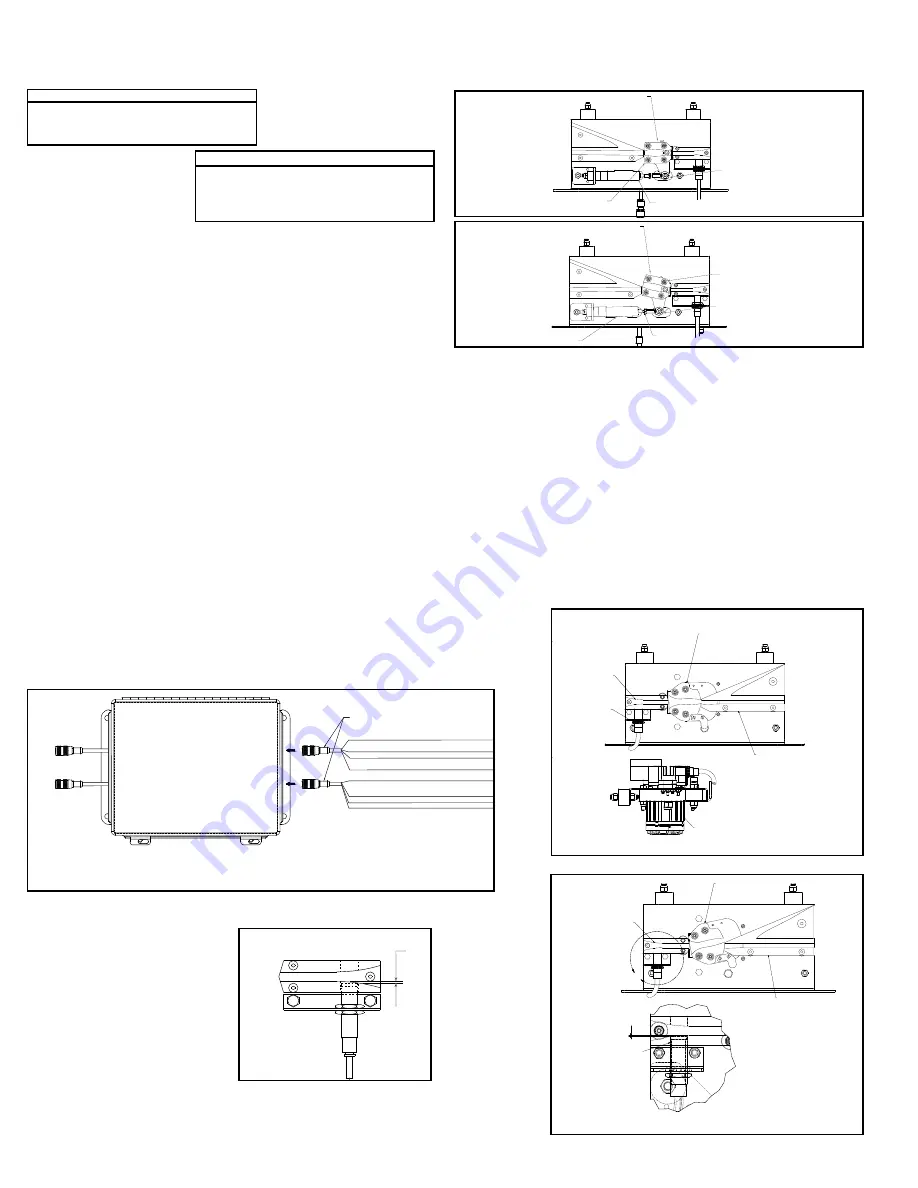

• Pneumatic Divert

Switch Checklist

After all ProSort sections are installed

and aligned, each divert switch should be

checked for proper operations as follows:

1. Before air pressure is supplied to the

divert switch solenoid air valve, manually

pivot the switch back and forth between

the non-divert and divert position

checking for a free and smooth pivoting

movement. Determine and remedy the

cause of any switch binding. For proper switch alignment see figures 8C & 8D.

If switch adjustment is necessary, loosen the jam nut on the cylinder rod. Screw

cylinder rod into or out of rod end to adjust the switch and retighten jam nut.

2. Turn air pressure on and verify that each divert switch is in, or moves to, the

home (non-divert) position (Figure 8C).

3. Check to insure that the smart prox is set properly. The face of the prox should

be set just out of the shoe pin guide path in the switch guide (Figure 8B)

•Electric Divert Switch Checklist

NOTE: All electric divert servo motors are paired with the associated drives at the

factory. Connecting motors to the wrong drive may have an adverse effect on the

divert operation and could result in physical damage to the sorter. Always connect

the drives to the factory paired motors to prevent damage.

1. Before running the sorter, apply power to the electric switch system and verify

that the diverts are fully in either the home or diverted position. Divert function was

tested at the factory to ensure proper operation. If the diverts are in the diverted

position, they can be returned to the home position, Figure 8E by removing the

enable signal to the Smart Prox and then flagging the Smart Prox to trigger a

move operation.

2. Each time diverts are powered on, the diverter will move slowly until it finds the

home position.

3. Ensure that the “All Systems Go” signal is on before running the sorter.

4. Check to ensure that the Smart Prox is set properly. The face of the prox should

be set just out of the shoe pin guide path in the switch guide (Figure 8F).

SWITCH BLOCK

(INTERRUPTOR DE

BLOQUEO)

ROD END

(EXTREMO DEL EJE)

NON-DIVERT POSITION

(POSICION DESVIADORA)

AIR CYLINDER EXTENDER

(EXTREMO DEL EJE)

SWITCH BLOCK

(INTERRUPTOR DE

BLOQUEO)

ROD END

(EXTREMO DEL EJE)

DIVERT POSITION

(POSICION DESVIADORA)

AIR RETRACTED

(EXTREMO DEL EJE)

JAM NUT

(CONTRA TUERCA)

FIGURE 8D

* BROKEN PROX OUTPUT IS ONLY ACTIVE WHEN SORTER RUN INPUT IS ACTIVE.

BROWN/

CAFÉ

NOT USED

BLACK/

NEGRO

OUPUT (24V=OK, 0V=MISSING BEARING DETECTED)

SALIDA (24 V = CORRECTO, 0 V = COJINETE FALTANTE DETECTADO)

BLUE/

AZUL

COMMON/

COMÚN

WHITE/

BLANCO

BROKEN PROX ERROR (24=OK, 0V=ERROR)/

ERROR DE SENSOR DE PROXIMIDAD DAÑADO (24 = CORRECTO, 0 V = ERROR)

BROWN

/

CAFÉ

POWER (+24VDC)/

ENERGÍA (+24 V CC)

BLACK/

NEGRO

RESET ERROR INPUT/

ENTRADA DE ERROR DE RESTABLECIMIENTO

BLUE

/

AZUL

COMMON/

COMÚN

WHITE

/

BLANCO

SORTER RUNNING INPUT (SORTER UP TO SPEED)

ENTRADA DE CLASIFICADOR EN FUNCIONAMIENTO

(CLASIFICADOR A VELOCIDAD NORMAL)

941.423003

OUTPUT

INPUT

TO PROX 2

TO PROX 1

(HACIA SENSOR DE

PROXIMIDAD 1)

(HACIA SENSOR DE

PROXIMIDAD 2)

(SALIDA)

(ENTRADA)

(LA SALIDA DE SENSOR DE PROXIMIDAD DAÑADO SOLO SE ACTIVA CUANDO LA

ENTRADA DE FUNCIONAMIENTO DEL CLASIFICADOR ESTÁ ACTIVA.)

FIGURE 8A

FIGURE 8C

1/32"

FIGURE 8B

V

V

NON-DIVERT POSITION

SERVO MOTOR

DIVERT BLOCK

PROX SWITCH

SWITCH GUIDE

NON-DIVERT POSITION

(POSICIÓN SIN DESVIACIÓN)

(GUÍA DEL

INTERRUPTOR)

(INTERRUPTOR

DE PROXIMIDAD)

(BLOQUE DE DESVIACIÓN)

(POSICIÓN SIN DESVIACIÓN)

(SERVOMOTOR)

FIGURE 8E

U

DIVERT POSITION

DIVERT BLOCK

SWITCH GUIDE

SWITCH BLOCK

PROX SWTICH

DETAIL U

SCALE 1.50 : 1

1/32

(BLOQUE DEL

INTERRUPTOR)

(GUÍA DEL

INTERRUPTOR)

(INTERRUPTOR

DE PROXIMIDAD)

(BLOQUE DE

DESVIACIÓN)

(POSICIÓN DE

DESVIACIÓN)

(DETALLE U)

(ESCALA 1.50: 1)

FIGURE 8F

ProSort 121 (22° Diverts)

0” < W ² 6”

Minimum gap = 6”

6” < W ² 18”

Minimum gap = 9”

18” < W ² 30”

Minimum gap = 12”

ProSort 131 (30° Diverts)

0” < W ² 6”

Minimum gap = 6”

6” < W ² 12”

Minimum gap = 9”

12” < W ² 18”

Minimum gap = 12”

18” < W ² 24”

Minimum gap = 15”

8