8

torque value shown in the MAINTENANCE SCHED-

ULE.

NOTE: Whenever a wheel is removed, it will be neces-

sary to lubricate the wheel nuts and studs. (See

FIGURE 37.) Put two drops of engine oil (or other lubri-

cant) between the flange and body of the wheel nut. Also

put two drops of oil on the threads of the studs.

9447

3

1

2

1

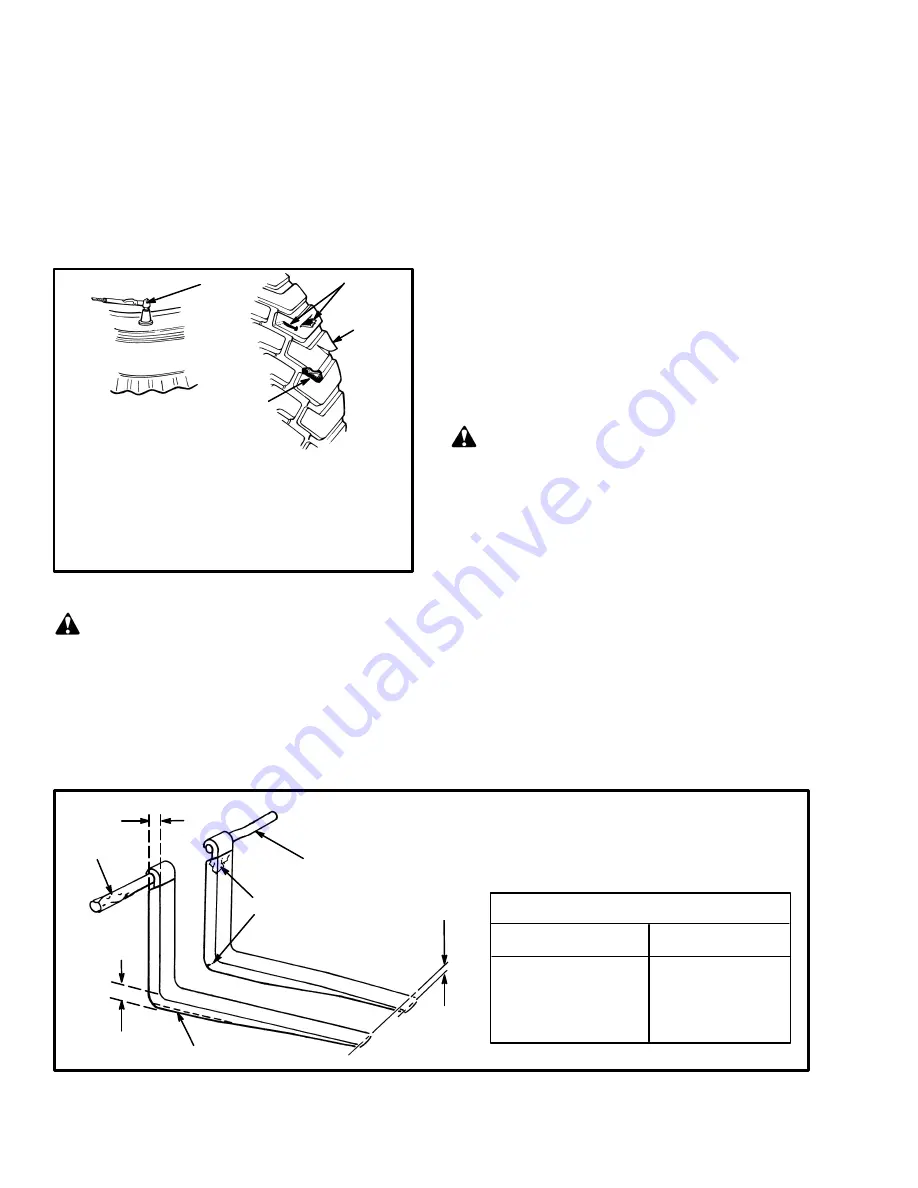

1. CHECK FOR DAMAGE (REMOVE NAILS,

GLASS AND OTHER OBJECTS FROM

THE TREAD)

2. MAKE SMOOTH EDGES

3. CHECK THE TIRE PRESSURE

(PNEUMATIC TIRES)

FIGURE 4. CHECK THE TIRES

CAUTION

When the wheels have been installed check all wheel

nuts after 2 to 5 hours of operation. Tighten the nuts

in a cross pattern to the correct torque value shown

in the MAINTENANCE SCHEDULE table. When

the nuts stay tight after eight hours, the interval for

checking the torque can be extended to 150 hours.

Forks

The identification of a fork is determined by how it is

connected to the carriage. These lift trucks have pin

forks. Pin forks are fastened to the carriage with large

fork pins.

Forks, Adjustment

A lock pin for each fork fits into the top carriage bar and

a slot in the fork. These lock pins hold the fork in posi-

tion. Adjust the forks as far apart as possible for maxi-

mum support of the load. Make sure the lock pin is en-

gaged in the carriage bar and the fork. The fork must be

locked into position after the adjustment is made.

Forks, Removal

WARNING

Do not try to move a fork without a lifting device.

The forks can weigh up to 370 kg (800 lb) each.

Put the lift truck on a level surface and lower the forks.

Tilt the mast so that the forks have stability. Remove the

retainers for the fork pins and push the pins from the car-

riage. Move the lift truck away from the forks.

Forks, Installation

1. Put the forks approximately 1 m (3 ft) in front of the

carriage.

2. Slowly move the lift truck toward the forks until the

fork pins can be installed. Install the fork pins and the

retainers.

3. FORK PIN DAMAGE

4. MUST BE 90% OF

DIMENSION X

5. FORK WEAR

1

5

3

3

2

11195

FIGURE 5. CHECK THE FORKS

X

4

1. TIP ALIGNMENT

(MUST BE WITHIN 3%

OF FORK LENGTH)

2. CRACKS

FORK TIP ALIGNMENT

LENGTH OF FORKS

3% DIMENSION

1220 mm (48 in)

37 mm (1.45 in)

1830 mm (72 in)

55 mm (2.15 in)

2440 mm (96 in)

74 mm (2.90 in)