OPERATION

4-18

HySpeed HT2000LHF

Instruction Manual

7

Shield

Arc

Approx.

Material

Plasma Gas Flow Rate %

Gas (O

2

)

Torch-to-work

Initial Torch

Voltage

Motion

Thickness

Preflow

Cutflow

Pressure

Distance

Piercing Height

Setting

Travel Speed

Delay Time

(inches)

(mm)

(O

2

% N

2

%) (O

2

% N

2

%)

(psi)

(inches)

(mm)

(inches)

(mm)

(volts)

(ipm) (mm/min.)

(sec)

.048 (18 GA.)

3

27

30

0

18

.060

1.50

.120

3.0

108

160

4060

0

.074 (14 GA.)

2 / 17

18 / 0

17

.060

1.50

.120

3.0

108

120

3050

0.3

.100 (12 GA.)

l/min

l/min

l/min

.070

1.75

.140

3.5

113

100

2540

0.3

.125 (10 GA.)

.080

2.00

.160

4.0

118

60

1520

0.5

Mild Steel

50 amps • O

2

Plasma / O

2

Shield

Notes:

Set oxygen plasma gas inlet pressure to 120 psi (8.3 bar)

Set nitrogen plasma gas inlet pressure to 120 psi (8.3 bar)

Set shield gas inlet pressure to 120 psi (8.3 bar)

The oxygen shield gas must be supplied from a regulator separate from the oxygen plasma gas regulator.

If using the Digital Remote (DR) or Programmable Remote (PR), set current to 60 amps.

If using a torch height control system capable of achieving the arc voltage setting on this chart, set accordingly.

If using a less sensitive torch height control system, round off the arc voltage numbers to the nearest achievable

setting.

Torch-to-work Distance tolerances are ± .010 inch (± .25 mm). When using a THC the tolerances are ± 1 volt.

Stay within travel speed ranges to produce dross-free cuts.

Due to the low gas flow rates associated with the 50 amp process, initial cut quality may be degraded while nitrogen is

being purged from the gas line when changing from preflow to cut flow (up to 2 seconds). To compensate, either

increase machine motion delay or increase the lead-in distance at the start of the cut.

Note that some height control systems may need to be locked out to prevent the torch from diving into the plate if the

machine motion delay option is used.

Above Water Only

120185

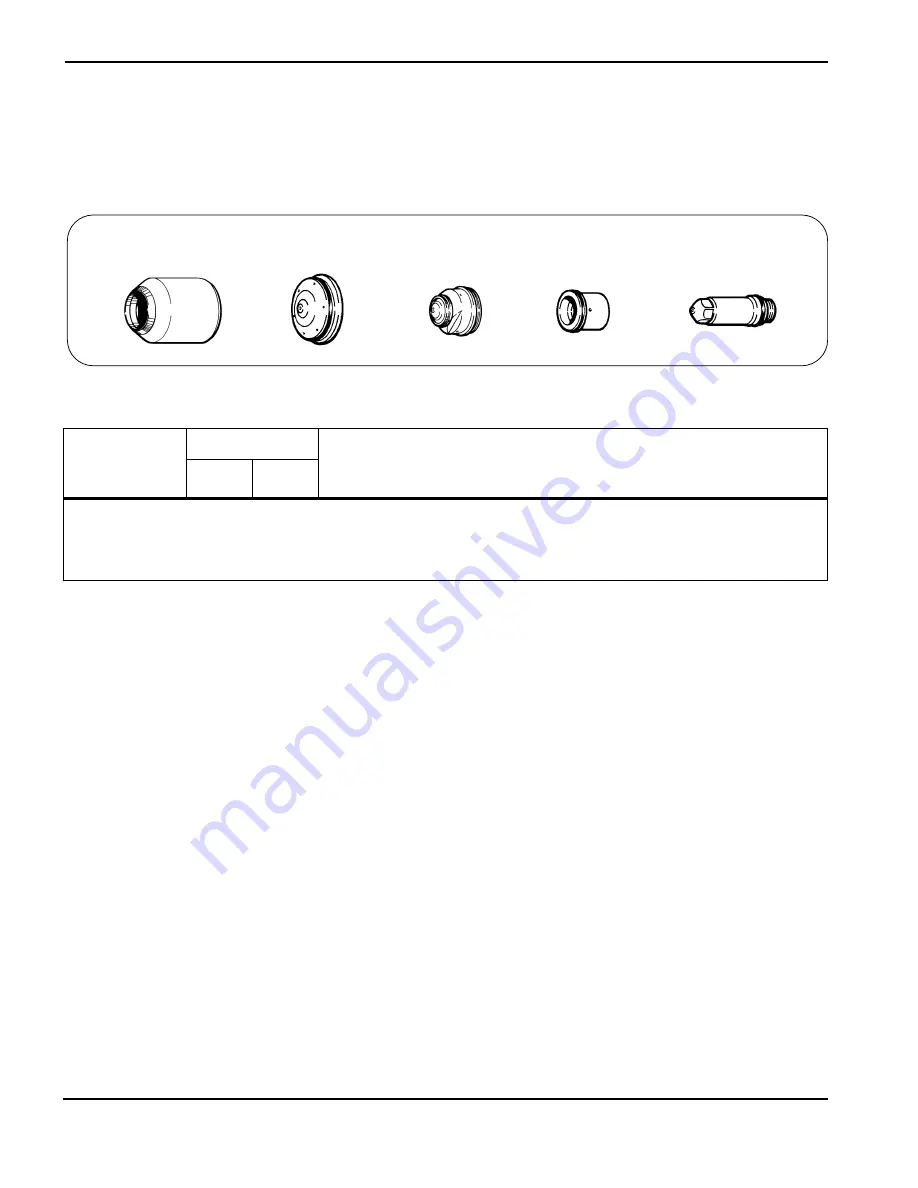

Retaining cap

120186

Shield

120182

Nozzle

120179

Swirl ring

120178

Electrode

Содержание HT2000LHF

Страница 1: ...200 Volt Plasma Arc Cutting System Instruction Manual 803040 Revision 7 HySpeed HT2000LHF ...

Страница 5: ......

Страница 15: ...TABLE OF CONTENTS viii Hyspeed HT2000LHF Instruction Manual 6 ...

Страница 109: ...MAINTENANCE 5 20 HySpeed HT2000LHF Instruction Manual 7 ...

Страница 133: ......

Страница 134: ...7 5 7 Figure 7 1 HT2000LHF Coolant Flow Diagram ...

Страница 135: ......

Страница 136: ...7 7 7 ...

Страница 137: ......

Страница 138: ...7 9 7 ...

Страница 139: ......

Страница 140: ...7 11 7 ...

Страница 141: ......

Страница 142: ...7 13 7 ...

Страница 143: ......

Страница 144: ...7 15 7 ...

Страница 145: ......

Страница 146: ...7 17 7 ...

Страница 147: ......

Страница 148: ...7 19 7 ...

Страница 149: ......

Страница 150: ...7 21 7 ...

Страница 151: ......

Страница 152: ...7 23 7 ...

Страница 153: ......

Страница 154: ...7 25 7 ...

Страница 155: ......

Страница 157: ......

Страница 159: ......

Страница 174: ...APPENDIX A ARGON HYDROGEN CUTTING AND GOUGING a 14 HySpeed HT2000LHF Instruction Manual 6 ...

Страница 176: ...b 2 ...

Страница 177: ...b 3 ...

Страница 178: ...b 4 ...

Страница 179: ...b 5 ...

Страница 181: ...b 7 ...

Страница 182: ...b 8 ...

Страница 183: ...b 9 ...

Страница 184: ...b 10 ...

Страница 194: ...APPENDIX E AIR FILTERS e 2 Hyspeed HT2000LHF Instruction Manual 6 ...

Страница 196: ...APPENDIX F AERATION MANIFOLD FOR CUTTING ALUMINUM f 2 Hyspeed HT2000LHF Instruction Manual 6 ...

Страница 198: ...APPENDIX G IEC SYMBOLS g 2 Hyspeed HT2000LHF Instruction Manual 6 ...