9

OPERATION

4-12

HySpeed HT2000LHF

Instruction Manual

Shield

Arc

Approx.

Material

Plasma Gas Flow Rate %

Gas (Air)

Torch-to-work

Initial Torch

Voltage

Motion

Thickness

Preflow

Cutflow

Pressure

Distance

Piercing Height

Setting

Travel Speed

Delay Time

(inches)

(mm)

(O

2

% N

2

%) (O

2

% N

2

%)

(psi)

(inches)

(mm)

(inches)

(mm)

(volts)

(ipm) (mm/min.)

(sec)

Shield

Arc

Approx.

Material

Plasma Gas Flow Rate %

Gas (Air)

Torch-to-work

Initial Torch

Voltage

Motion

Thickness

Preflow

Cutflow

Pressure

Distance

Piercing Height

Setting

Travel Speed

Delay Time

(inches)

(mm)

(O

2

% N

2

%) (O

2

% N

2

%)

(psi)

(inches)

(mm)

(inches)

(mm)

(volts)

(ipm) (mm/min.)

(sec)

1/4

6

12

38

76

0

60

1/16

1.5

1/8

3

145

230

5800

0.3

5/16

8

(12 / 50

(90 / 0

(275

1/8

3

1/4

6

151

165

4200

0.3

3/8

10

SCFH)

SCFH)

SCFH)

5/32

4

5/16

8

155

140

3500

0.3

1/2

12

1/8

3

1/4

6

155

120

3000

0.3

5/8

15

1/8

3

1/4

6

155

100

2500

0.5

3/4

20

1/8

3

1/4

6

155

75

1900

0.6

7/8

22

1/8

3

1/4

6

159

60

1500

0.7

1

25

1/8

3

1/4

6

160

50

1300

0.7

1 1/4

32

1/8

3

5/16

8

168

30

760

2.6

1-1/2

38

1/8

3

5/16

8

175

20

500

4.0

1-3/4

44

1/8

3

N/A

N/A

180

15

380

N/A

2

50

1/8

3

N/A

N/A

188

10

250

N/A

Mild Steel

HySpeed 200 amps • O

2

Plasma / Air Shield

This gas combination gives superior cut speed, minimum dross, minimum surface nitriding and excellent

weldability.

Notes:

Set oxygen plasma gas inlet pressure to 120 psi (8.3 bar).

Set nitrogen plasma gas inlet pressure to 120 psi (8.3 bar)

Set shield gas inlet pressure to 90 psi (6.2 bar)

Production cutting above 1" (25 mm) not recommended.

Drop cutting above 1-1/2" (38 mm) not recommended

Above Water

1/4

6

12

38

76

0

60

1/16

1.5

1/8

3

149

230

5800

0.3

5/16

8

(12 / 50

(90 / 0

(275

1/8

3

1/4

6

151

165

4200

0.3

3/8

10

SCFH)

SCFH)

SCFH)

5/32

4

5/16

8

159

140

3500

0.3

1/2

12

1/8

3

1/4

6

155

105

2700

0.3

5/8

15

1/8

3

1/4

6

161

90

2300

0.5

3/4

20

1/8

3

1/4

6

161

65

1600

0.6

7/8

22

1/8

3

1/4

6

161

55

1400

0.7

1

25

1/8

3

1/4

6

164

45

1100

0.7

3" Under Water

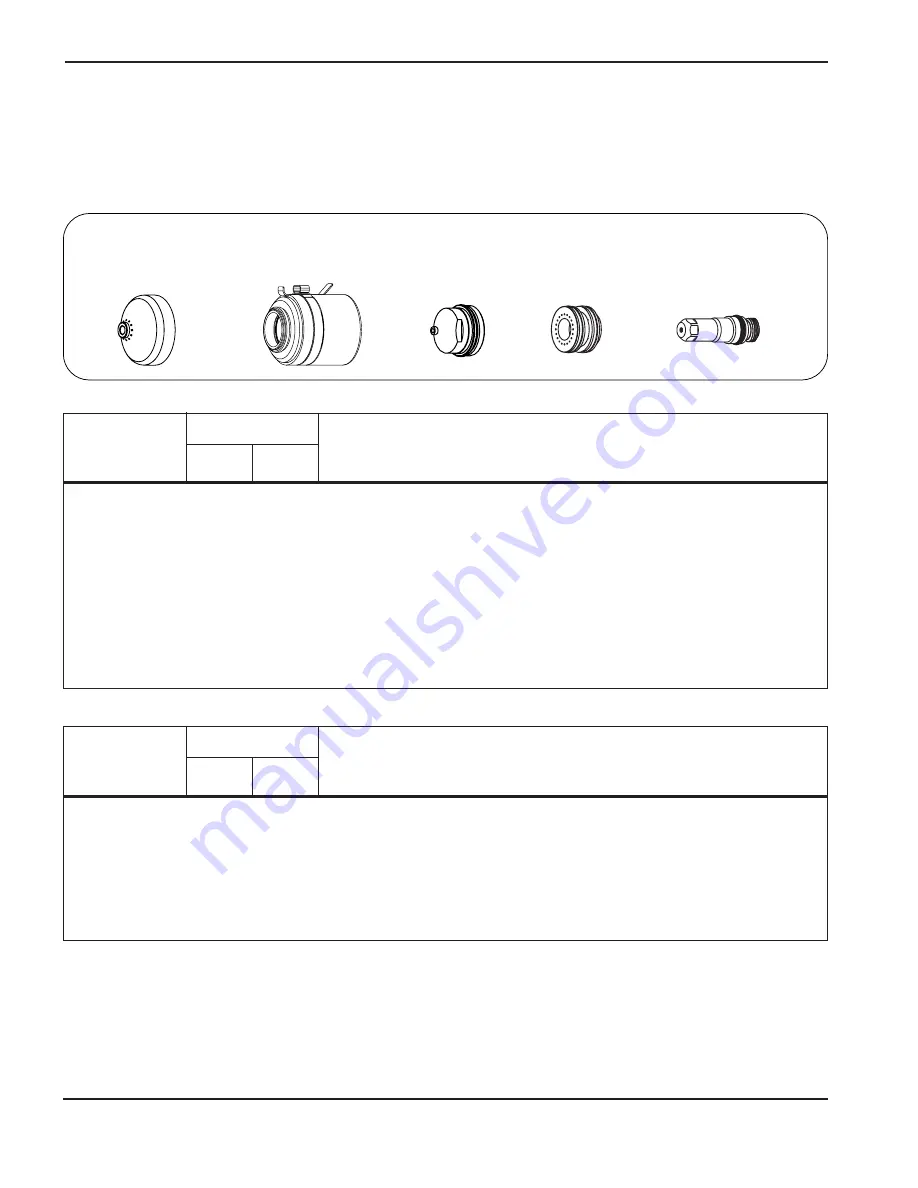

220235

Electrode

220237

Nozzle

220242

(cw)

220243

(ccw)

Retaining cap

220239

Shield

220236

(cw)

220244

(ccw)

Swirl ring

Содержание HT2000LHF

Страница 1: ...200 Volt Plasma Arc Cutting System Instruction Manual 803040 Revision 7 HySpeed HT2000LHF ...

Страница 5: ......

Страница 15: ...TABLE OF CONTENTS viii Hyspeed HT2000LHF Instruction Manual 6 ...

Страница 109: ...MAINTENANCE 5 20 HySpeed HT2000LHF Instruction Manual 7 ...

Страница 133: ......

Страница 134: ...7 5 7 Figure 7 1 HT2000LHF Coolant Flow Diagram ...

Страница 135: ......

Страница 136: ...7 7 7 ...

Страница 137: ......

Страница 138: ...7 9 7 ...

Страница 139: ......

Страница 140: ...7 11 7 ...

Страница 141: ......

Страница 142: ...7 13 7 ...

Страница 143: ......

Страница 144: ...7 15 7 ...

Страница 145: ......

Страница 146: ...7 17 7 ...

Страница 147: ......

Страница 148: ...7 19 7 ...

Страница 149: ......

Страница 150: ...7 21 7 ...

Страница 151: ......

Страница 152: ...7 23 7 ...

Страница 153: ......

Страница 154: ...7 25 7 ...

Страница 155: ......

Страница 157: ......

Страница 159: ......

Страница 174: ...APPENDIX A ARGON HYDROGEN CUTTING AND GOUGING a 14 HySpeed HT2000LHF Instruction Manual 6 ...

Страница 176: ...b 2 ...

Страница 177: ...b 3 ...

Страница 178: ...b 4 ...

Страница 179: ...b 5 ...

Страница 181: ...b 7 ...

Страница 182: ...b 8 ...

Страница 183: ...b 9 ...

Страница 184: ...b 10 ...

Страница 194: ...APPENDIX E AIR FILTERS e 2 Hyspeed HT2000LHF Instruction Manual 6 ...

Страница 196: ...APPENDIX F AERATION MANIFOLD FOR CUTTING ALUMINUM f 2 Hyspeed HT2000LHF Instruction Manual 6 ...

Страница 198: ...APPENDIX G IEC SYMBOLS g 2 Hyspeed HT2000LHF Instruction Manual 6 ...