7

Gas-Fired Direct Vent Cast Iron Boilers – Field Assembly Instructions

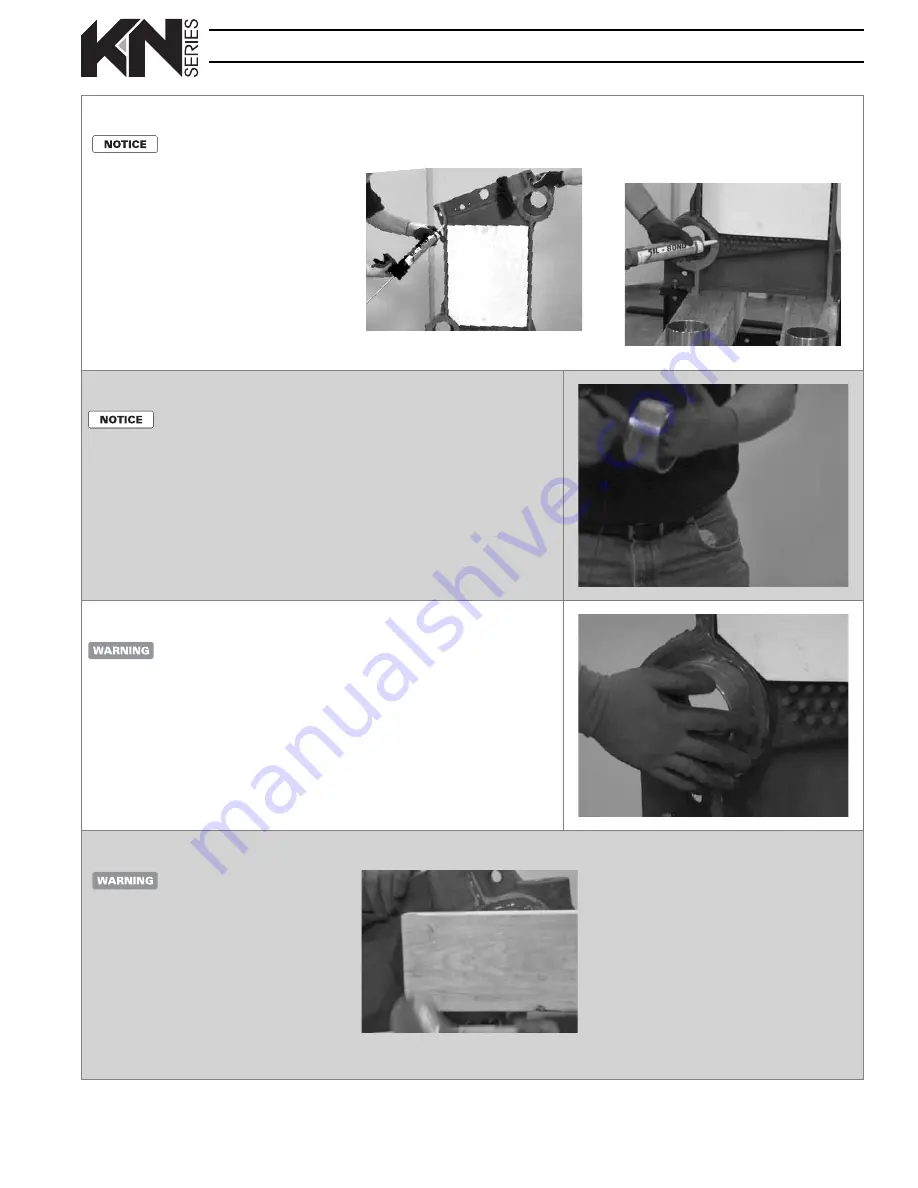

Step 10

Apply RTV to machined surfaces

Rubber gloves are

recommended for this

procedure.

1. Apply a bead of silicone RTV (supplied

with boiler) on the perimeter surfaces

of the section and around the INSIDE

edges of the nipple ports.

2. This is necessary to form a seal between

the sections. The seal prevents fl ue

gases from escaping.

3. Extend the bead all the way from the

top of the section to the bottom.

4. Keep the bead of silicone close to the

INSIDE edge of the nipple ports.

5. This will protect the machined nipple

port surfaces from condensation that

may occur in the fl ueways.

Step 11

Lubricate push nipples with oil/pipe dope mixture (see Step 8)

Inspect push nipples carefully

before using.

DO NOT

use

a nipple if it is gouged or

scarred.

DO NOT apply excessive

lubricant to the nipple

ports

. Lubricant can drip

onto the machined sealing

surface, preventing the

RTV sealant used later from

sticking.

1. Obtain two push nipples.

2. Inspect carefully and wipe off the

nipples with a clean cloth.

3. Brush the outside surface of each

push nipple VERY LIGHTLY with the

push nipple lubricant.

4. Wipe

off any excess lubricant.

Step 12

Insert push nipples

Avoid scarring or damaging

the push nipple or nipple

port surfaces. Th e push

nipple makes a metal-to-

metal seal with the nipple

port. Any surface defects

could cause a leak.

1. Insert a push nipple into each of the

two nipple ports.

2. Seat each nipple fi rmly but squarely.

3. Make sure the nipple face is parallel

to the section surface as closely as

possible.

4. DO NOT attempt to assemble sections

if any nipple port is mis-aligned.

Step 13

Seat the push nipples

Use only a dead blow hammer

to seat the push nipples. DO

NOT use a sledge hammer.

1. Place a 2x4 board across the nipple and

strike fi rmly with a dead-blow hammer.

2. Make sure to strike in the center of the

nipple to prevent rotating it.

3. Do this with several strokes, just so the

push nipple is fi rmly started.

4. Look into the nipple ports from the end

of the boiler. When properly seated at

this point, the push nipple edge should

be slightly inside the nipple port. It

should also be parallel with the inside

surface.