The table below shows the coding system for the fitting connections.

Each fitting has a unique “keyed” socket on the manifold. Each

fitting also has a graphic symbol molded into the elbow with a

corresponding symbol on the manifold.

Connector Symbol

Connection

Tubing Color

`

Feed-Inlet

Natural

—

Concentrate

Black

*

Product

Blue

WARNING:

Be sure to lubricate the manifold ports with silicone

lubricant, prior to inserting the fittings into manifold.

WARNING:

Do not turn the incoming water valve on until the

locking bar is in place.

When all of the connections have been made, use the locking bar to

hold the fittings in position. Match the symbols on the locking bar to

the corresponding symbols on the manifold (Figure 12).

Step 6: System Startup

Inspect all connections.

1.

Position manifold horizontal with openings facing up.

2.

Remove new membrane elements from plastic packaging. The

3.

blue and green tape surrounding the membrane are an important

part of the membrane element and should not be removed.

CAUTION:

Elements contain a foodgrade preservative. The use of

sterile/latex gloves is recommended.

Lubricate all O-ring seats in the manifold that come in contact

4.

with the sump and element O-rings. Refer to "Connection

Lubrication" on page 8.

NOTE: To properly lubricate the O-ring contact area, a film of clean

silicone grease is applied. The film should cover all of the

surface area that the O-ring will slide over and seal with. Do

not use grease containing petroleum products.

Securely insert O-ring end of membrane elements into manifold.

5.

Push the membrane straight down into the hole in the manifold.

Do not twist or rock the membrane when intsalling, as this may

damage the o-rings.

Remove pre-filter from packaging. Check that gaskets are in

6.

place.

Place pre-filter in manifold.

7.

Replace sumps and tighten until it bottoms out. (DO NOT

8.

OVERTIGHTEN)

Pressure Test System

To check for leaks, the system must be filled with water and brought

up to operating pressure.

Open cold water feed valve slowly. Run at 1/2 open for a minute,

1.

then open fully.

Make sure included shut off valve installed on the blue purified

2.

water line is in the open position.

Check for leaks.

3.

NOTE: When the system is initially turned on, water may temporarily

sputter all the air is purged. Allow 1 to 3 hours for any trapped

air noise in the system to subside.

Purge the system. Run the water through the RO system allowing

4.

all water to go to drain for two to eight hours to stabilize the pH

and PPM’s of the purified water

NOTE: A minimum of a 2 hour flush is required to remove the food

grade preservative. After 8 hours performance will reach its

stable maximum performance.

The RO system is now ready for use.

Symbols

INSTALLATION cont.

Figure 6

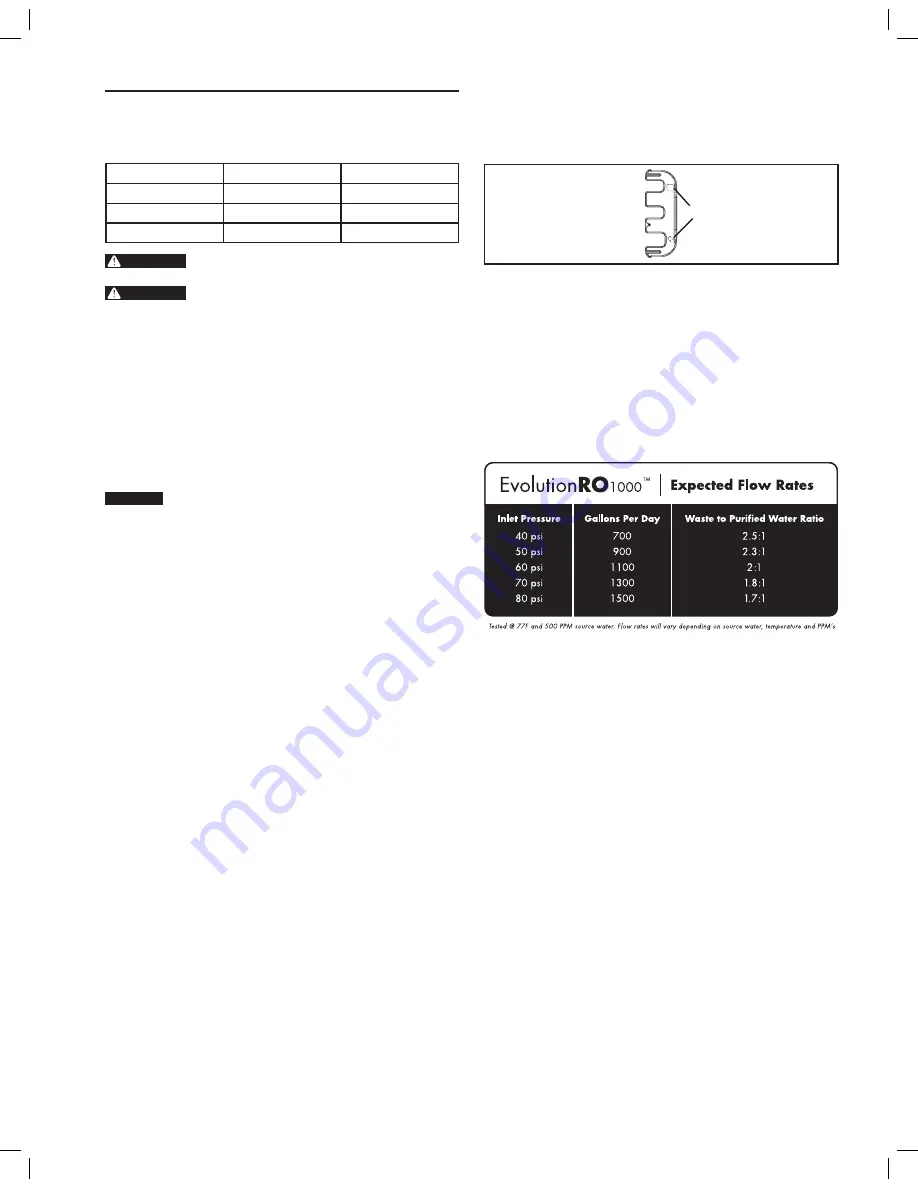

NOTE: The flow ratre of purified water will vary depending on 3

factors:

- Inlet water pressure

- Inlet water temperature

- Inlet water PPM

9

Содержание EVOLUTION-RO1000

Страница 1: ...Installation Maintenance Manual ...

Страница 16: ...GL4000442 RevA ...