8

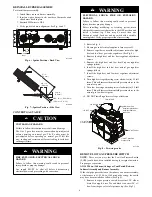

CHECK INLET GAS PRESSURE

UNIT DAMAGE HAZARD

Failure to follow this caution may result in unit damage.

DO NOT operate furnace more than one minute to check

inlet gas pressure, as conversion is not complete at this time.

CAUTION

!

NOTE

: This kit is to be used only when inlet gas pressure is

between 4.5--in. W.C. and 13.6--in. W.C.

1. Verify manometer is connected to inlet pressure tap on gas

valve. See Fig. 8.

2. Turn on furnace power supply.

3. Turn gas supply manual shutoff valve to ON position.

FIRE, EXPLOSION, ELECTRICAL SHOCK

HAZARD

Failure to follow this warning could result in personal

injury, death or property damage.

Gas supply MUST be shut off before disconnecting

electrical power and proceeding with conversion.

!

WARNING

ELECTRICAL SHOCK, FIRE OR EXPLOSION

HAZARD

Failure to follow this warning could result in personal

injury, death or property damage.

Before installing, modifying, or servicing system, main

electrical disconnect switch must be in the OFF position and

install a lockout tag. There may be more than one

disconnect switch. Lock out and tag switch with a suitable

warning label. Verify proper operation after servicing.

!

WARNING

4. Turn furnace gas valve switch to ON position.

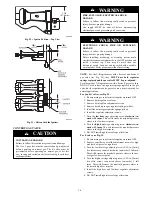

5. Turn Setup Switch SW1 (LHT) on furnace control ON

(see Fig. 11).

TEST / TWIN

HUM

PL

T

SEC-2

SEC-1

COM

24VAC

PL1

W2 Y

DHUM G COM W/W1 Y/Y2 R

24V

FUSE 3-AMP

EAC-2

EAC-1

L1

BL-1

PR-1

L2

COM

HI HT

COOL

LO HT

SPARE 2

24V MTR

TA

P

S

BLOWER SPEED

TERMINALS

115-VAC (L2)

NEUTRAL

CONNECTIONS

LED OPERATION

& DIAGNOSTIC LIGHT

3-AMP FUSE

24-V THERMOSTAT

TERMINALS

SET UP SWITCHES

LOW HEAT ONLY

AND BLOWER

OFF-DELAY

TWINNING AND/OR

COMPONENT TEST

TERMINAL

ACRDJ - AIR CONDITIONING

RELAY DISABLE JUMPER

HUMIDIFIER TERMINAL

(24 VAC 0.5 AMPS MAX)

TRANSFORMER

24 VAC CONNECTIONS

PL1-LOW VO LTAGE

MAIN HARNESS CONNEC TOR

PL2 - HOT SURFACE

IGNITER/INDUCE R

MOTOR CONNECTION

115 VAC

BLOWER POWER (BL1)

CONNECTION

115 VAC LINE (L1)

INPUT

LHT

OFF

DLY

ON

OFF

1 2 3

IDR

HSIR

IDM

IHI/L

OR

PL2

1

HSI HI LO

1

EAC TERMINAL

115 VAC 1.0 AMP MAX

115 VAC

TRANSFORMER

PRIMARY

SPARE 1

A11470

Fig. 11 -- Two--stage Furnace Control

6. Jumper R--W/W1 and R--W2 thermostat connections on

control.

7. When main burners ignite, confirm inlet gas pressure is

between 4.5--in. W.C. and 13.6--in. W.C.

8. Remove jumper across R--W/W1 and R--W2 thermostat

connections to terminate call for heat.

9. Turn furnace gas valve switch to OFF position.

10. Turn gas supply manual shutoff valve to OFF position.

11. Turn off furnace power supply.

12. Remove manometer.

13. Apply pipe dope sparingly to the 1/8-in. NPT pipe plug

and install in the 1/8-in. tapped inlet pressure tap opening

in the gas valve. DO NOT over--tighten. Check for gas

leaks after gas supply has been turned on.

CHECK FURNACE AND MAKE ADJUSTMENTS

FIRE AND EXPLOSION HAZARD

Failure to follow this warning could result in personal injury

and/or death.

NEVER test for gas leaks with an open flame. Use a

commercially available soap solution made specifically for

the detection of leaks to check all connections. A fire or

explosion may result causing property damage, personal

injury or loss of life.

!

WARNING

RISQUE D’EXPLOSION ET D’INCENDIE

Le fait de ne pas suivre cet avertissement pourrait entraîner des

dommages corporels et / ou la mort.

Ne jamais examiner pour les fuites de gaz avec une flamme

vive. Utilisez plutôt un savon fait specifiquement pour la

détection des fuites de gaz pour verifier tous les connections.

Un incendie ou une explosion peut entrainer des dommages

matériels, des blessures ou la mort.

!

AVERTISSEMENT

1. Be sure main gas and electric supplies to furnace are off.

2. Remove 1/8-in. NPT pipe plug from manifold pressure tap

on downstream side of gas valve.

3. Attach manometer to manifold pressure tap on gas valve.

(see Fig. 8.)

4. Turn gas supply manual shutoff valve to ON position.

5. Turn furnace gas valve switch to ON position.

6. Check all threaded pipe connections for gas leaks.

7. Turn on furnace power supply.

GAS INPUT RATE INFORMATION

See furnace rating plate for input rate. The input rate for natural

gas is determined by manifold pressure and orifice size.

Determine natural gas orifice size and manifold pressures for

correct input at installed altitude by using Table 3.

1. Obtain yearly heat--value average (at installed altitude) for

local gas supply.

2. Obtain yearly specific--gravity average for local gas sup-

ply.

3. Find installation altitude in Table 3.

NOTE

: For Canada altitudes of 2000 to 4500 ft. (610 to 1372

M), use U.S.A. Altitudes of 2001 to 3000 ft. (610 to 914 M) in

Table 3.

Содержание KGAPN43012SP

Страница 10: ...10 A11514 Fig 13 Conversion Responsibility Label A11515 Fig 14 Conversion Kit Rating Plate Label ...

Страница 14: ...14 Table 5 Orifice Size and Manifold Pressure In W C for Gas Input Rate A10184 ...

Страница 15: ...15 Table 5 Orifice Size and Manifold Pressure In W C for Gas Input Rate cont A10184A ...

Страница 16: ...16 Table 6 Orifice Size and Manifold Pressure In W C for Gas Input Rate A10185 ...