12

A03059

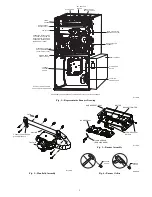

Fig. 15 -- Representative Furnace Drawing

MANIFOLD/ORIFICE/BURNER REMOVAL

UNIT OPERATION HAZARD

Failure to follow this caution may result in unit damage or

improper operation.

Label all wires prior to disconnection when servicing

controls.

CAUTION

!

D’EQUIPMENT D’OPERATION

Lors des opérations d’entretien des commandes, étiqueter

tous les fils avant de les déconnecter.

PRUDENCE

!

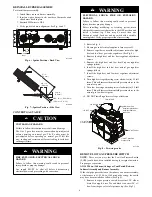

NOTE

: Use a back-up wrench on the gas valve to prevent the

valve from rotating on the manifold or damaging the mounting to

the burner box. See Fig. 16 & 17.

1. Disconnect the gas pipe from gas valve and remove pipe

from the furnace casing.

2. Disconnect the connector harness from gas valve Discon-

nect wires from Hot Surface Igniter (HSI) and Flame

Sensor. Disconnect the two wires from the Low Gas Pres-

sure Switch (LGPS) located on the gas valve.

3. Support the manifold and remove the 4 screws that secure

the manifold assembly to the burner box and set aside.

4. Note the location of the green/yellow wire ground wire for

re-assembly later.

5. Slide one--piece burner assembly out of slots on sides of

burner box.

6. Remove the flame sensor from the burner assembly.

7. Remove the orifices from the manifold and discard.

Attach Green/Yellow

ground wire here

Manifold Assy

Sensor Flame

Clip, Harness

Burner Assy

Burner Support Assy

Switch, Temp (2)

Ignitor

Bracket Ignitor

A11390

Fig. 16 -- 80% Burner

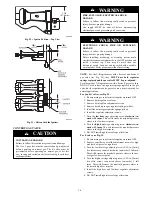

Gas Valve

Screw (2)

Attach Green/Yellow

ground wire here

Orifice

Manifold

A11395

Fig. 17 -- 80% Manifold

Содержание KGAPN43012SP

Страница 10: ...10 A11514 Fig 13 Conversion Responsibility Label A11515 Fig 14 Conversion Kit Rating Plate Label ...

Страница 14: ...14 Table 5 Orifice Size and Manifold Pressure In W C for Gas Input Rate A10184 ...

Страница 15: ...15 Table 5 Orifice Size and Manifold Pressure In W C for Gas Input Rate cont A10184A ...

Страница 16: ...16 Table 6 Orifice Size and Manifold Pressure In W C for Gas Input Rate A10185 ...