2

2

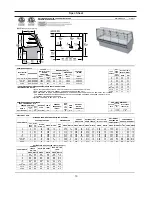

2. Temperature control should be by means of a

T-STAT and Suction Stop Solenoid at each case.

DO NOT use EPR valves, Liquid line solenoids

or electronic control devices of any kind, as these

allow temperature swings causing dehydration and

excessive energy consumption.

3. Discharge air temperature should be approximately

26°F, with between 150-200 FPM air velocity. Do not

display product directly within the air discharge.

4. Clean humidity system a minimum of every 90 days

for proper system operation.

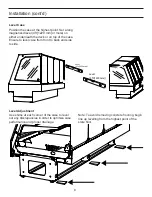

Case Cleaning

Long life and satisfactory performance of any equipment

are dependent upon the care given to it. To insure long

life, proper sanitation and minimum maintenance costs,

the refrigerator should be thoroughly cleaned frequently.

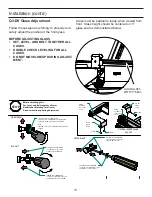

SHUT OFF FAN DURING CLEANING PROCESS. It can be

unplugged within the case, or shut off case at the source.

The interior bottom may be cleaned with any domestic soap

or detergent based cleaners. Sanitizing solutions will not

harm the interior bottom, however, these solutions should

always be used according to the manufacturer’s directions.

It is essential to establish and regulate cleaning procedures.

This will minimize bacteria causing discoloration which

leads to degraded product appearance and signifi cantly

shortening product shelf life.

Soap and hot water are not enough to kill this bacteria. A

sanitizing solution must be included with each cleaning

process to eliminate this bacteria.

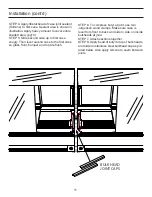

1. Scrub thoroughly, cleaning all surfaces, with soap

and hot water.

2. Rinse with hot water, but do not fl ood.

3. Apply the sanitizing solution according to

Hussmann’s directions.

4. Rinse thoroughly.

5. Dry completely before resuming operation.

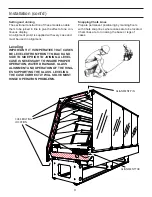

Cleaning Glass and Mirrors

Only use a soft cloth and water for cleaning any glass

or mirrored components. Be sure to rinse and/or dry

completely.

Never use hot water on cold glass surfaces! It may

shatter and cause serious injury!

Allow glass surfaces

to warm fi rst.

Non-Glare Glass

The high optical clarity of this glass is possible due to

special coatings on the glass surface itself. To preserve this

coating and the optical clarity, keep the glass clean.

Water is the only solution recommended for use in cleaning

non-glare glass. The damage to the glass from improper,

caustic solutions is irreparable. In addition to cleaning the

glass with the recommended product, there are precautions

that should be taken when working and cleaning the inside

of the case.

• When cleaning the inside of the cases, we

recommend that the glass be fully opened and

covered to prevent solutions from splashing onto the

glass and ruining the coating on the inside.

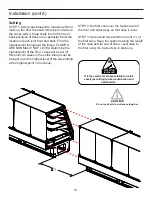

Plexiglass and Acrylic Care

Improper cleaning not only accelerates the cleaning cycle

but also degrades the quality of this surface. Normal daily

buffi ng motions can generate static cling attracting dust to

the surface. Incorrect cleaning agents or cleaning cloths

can cause micro scratching of the surface, causing the

plastic to haze over time.

Cleaning

Hussmann recommends using a clean damp chamois, or a

paper towel marketed as dust and abrasive free with

210

®

Plastic Cleaner and Polish

available by calling Sumner

Labs at

1-800-542-8656

. Hard, rough cloths or paper towels

will scratch the acrylic and should not be used.

Antistatic Coatings

The

210

®

has proven to be very effective in not only

cleaning and polishing the Plexiglass surface, but also

providing anti-static and anti-fog capabilities. This product

also seals pores and provides a protective coating.

User Information (Cont'd)