1

8

Plumbing

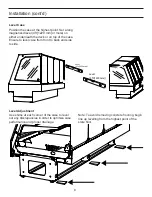

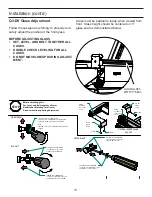

Waste Outlet and P-TRAP

The waste outlet is located off the center of the case on

one side allowing drip piping to be run lengthwise under

the fi xture.

A 1-1/2" P-TRAP and threaded adapter are supplied with

each

fi xture. The P-TRAP must be installed to prevent air

leakage and insect entrance into the fi xture.

NOTE: PVC-DWV solvent cement is recommended. Follow the

Hussmann’s instructions.

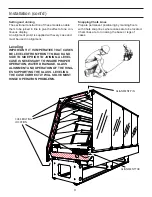

Installing Condensate Drain

Poorly or improperly installed condensate drains can

seriously interfere with the operation of this refrigerator, and

result in costly maintenance and product losses. Please

follow the recommendations listed below when installing

condensate drains to insure a proper installation:

1. Never use pipe for condensate drains smaller

than the nominal diameter of the pipe or P-TRAP

supplied with the case.

2. When connecting condensate drains, the P-TRAP

must be used as part of the condensate drain

to prevent air leakage or insect entrance. Store

plumbing system

fl oor drains should be at least 14”

off the center of the case to allow use of the P-TRAP

pipe section. Never use two water seals in series in

any one line. Double P-TRAPS in series will cause a

lock and prevent draining.

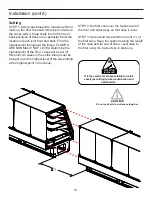

3. Always provide as much down hill slope (“fall”) as

possible; 1/8” per foot is the preferred minimum.

PVC pipe, when used, must be supported to

maintain the 1/8” pitch and to prevent warping.

4. Avoid long runs of condensate drains. Long runs

make it impossible to provide the “fall” necessary for

good drainage.

5. Provide a suitable air break between the fl ood rim of

the fl oor drain and outlet of condensate drain. 1” is

ideal.

6. Prevent condensate drains from freezing:

a. Do not install condensate drains in contact with

non-insulated suction lines. Suction lines should

be insulated with a non-absorbent insulation

material such as Armstrong’s Armafl ex.

b. Where condensate drains are located in dead

air spaces (between refrigerators or between a

refrigerator and a wall), provide means to prevent

freezing. The water seal should be insulated to

prevent condensation.

Refrigeration

Refrigerant Type

The standard refrigerant will be R-22 unless otherwise

specifi ed on the customer order. Check the serial plate on

the case for information.

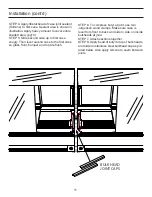

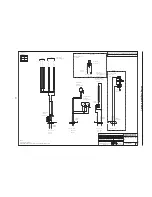

Piping

The refrigerant line outlets are located under the case.

Locate fi rst the electrical box, the outlets are then on the

same side of the case, but at the opposite end. Insulate

suction lines to prevent condensation drippage.

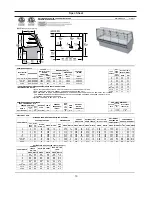

Refrigeration Lines

Liquid

Suction

3/8” O.D.

5/8” O.D.

NOTE: The standard coil is piped at

5

/

8

” (suction); however,

the store tie-in may vary depending on the number of

coils and the draw the case has. Depending on the case

setup, the connecting point in the store may be

5

/

8

”,

7

/

8

”,

or 1

1

/

8

”. Refer to the particular case you are hooking up.

Refrigerant lines should be sized as shown on the

refrigeration legend furnished by the store.

Install

P-TRAPS

(oil traps) at the base of all suction line

vertical risers.

Pressure drop

can rob the system of capacity. To keep the

pressure drop to a minimum, keep refrigerant line run as

short as possible, using the minimum number of elbows.

Where elbows are required, use long radius elbows only.

Control Settings

See Q3-DV technical data sheet for the appropriate

settings for your merchandiser. Maintain these parameters

to achieve near constant product temperatures. Product

temperature should be measured fi rst thing in the morning,

after having been refrigerated overnight. For all multiplexing,

defrost should be time terminated. Defrost times should be

as directed in the Q3-DV technical data sheet. The number

of defrosts per day should never change. The duration

of the defrost cycle may be adjusted to meet conditions

present at your location.

Access to TEV Valves and Drain Lines

Mechanical -

Remove product from case. Remove pans.

TX valve (mechanical only) and drain are located under

the pans within the case.

Electronic -

The Electronic Expansion valve master and

slave cylinder(s) are located within the electrical access

panel(s) in the rear of case. Unscrew the rear panels with

Phillips screwdriver.

Electronic Expansion Valve (Optional)

A wide variety of electronic expansion valves and case

controllers can be utilized. Please refer to EEV and

controller manufacturers information sheet. Sensors for

electronic expansion valves will be installed on the coil inlet,

coil outlet, and in the discharge air. (Some supermarkets

require a 4th sensor in the return air). Case controllers will

be located in the electrical raceway or under the case.