6

Operations & Parts Manual

Model No. CAT851

The amount of paint being applied can be varied by the speed

of the stroke, distance from the surface and adjustment of the

fluid control knob.

Overlap strokes just enough to obtain an even coat.

NOTE: Two thin coats of paint will yield better results and

have less chance of runs than one heavy layer.

Use a piece of cardboard as a shield to catch overspray at the

edges of the work to protect other surfaces.

The desired pattern and fine atomization can be easily

obtained by regulating the Pattern Adjusting Knob, Fluid

(PAINT) Adjusting Knob.

PATTERN ADJUSTMENT:

Turning Pattern Adjusting Knob to

the right until tight will make spray pattern round, or turning left

make spray pattern ellipse.

NOTE: To reduce over spray and obtain maximum

efficiency, always spray with the lowest possible

atomization air pressure.

Fluid (PAINT) ADJUSTMENT:

Turn the Paint Adjusting Knob

clockwise will decrease the volume of fluid output and

counter-clockwise will increase fluid output.

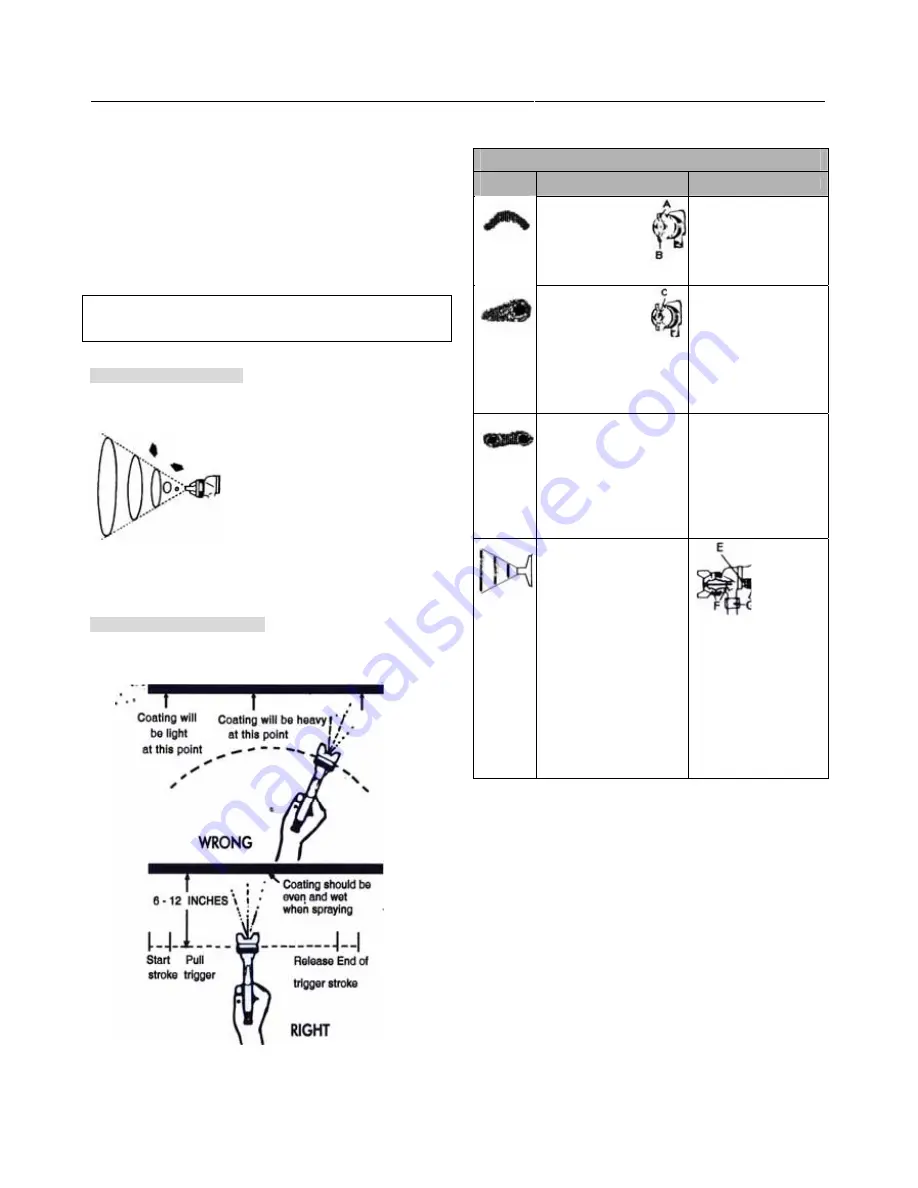

FAULTY SPRAY

( and how to correct it)

PATTER

N

CAUSE

CORRECTION

Dried material inside

port “A” restricts

passage of air.

Greater flow of air

from cleaner side-port

“B” forces fan pattern

in direction of clogged side

Dissolve material in

side-ports with thinner then

blow gun clean. Do not poke

into openings with metal

instruments

Dried material around

the outside of the fluid

nozzle tip at position

“C” restricts the

passage of atomizing

air at one point through the

center opening of air nozzle

and results in pattern shown,

this pattern can also be caused

by loose air nozzle.

Remove air nozzle and wipe

off fluid tip, using rag wet

with thinner. Tighten air

nozzle.

A split spray or one that is

heavy on each end of a fan

pattern and weak in the middle

is usually caused by

(1) too high an atomization air

pressure, or

(2) by attempting to get too

wide a spray with thin material.

Reducing air pressure will

correct cause (1).

To correct cause (2), open

material control to full

position by turning to left. At

the same time, turn spray

width adjustment to right.

This will reduce width of

spray, but will correct split

spray pattern.

To correct

cause (1).

Back up

knurled nut

(E) place two

drops of

machine oil

on packing,

(1) Dried out packing around

material needle valve permits

air to get into fluid passageway.

This results in splitting.

(2) Dirt between fluid nozzle

seat and body or loosely

installed fluid nozzle will make

gun split.

(3) A loose or defective swivel

nut on siphon cup or material

hose can cause spitting.

replace nut and tighten with

fingers only. In aggravated

cases, replace packing.

To correct cause (2),

remove fluid nozzle (F),

clean back of nozzle and

nozzle seat in gun body

using rag wet with thinner,

replace nozzle and draw up

tightly against body.

To correct cause (3), tighten

or replace swivel nut. (G).

1/2" Impact Wrench

The Husky 1/2

"

Impact wrench is supplied with an internal

power regulator (36). This tool may be adjusted by rotating the

regulator valve until desired output is achieved. The numbers 1

though 4 on the regulator are only for reference and do not

denote a specific power output. While pushing the regulator

turn to 4 for maximum power and turn to 1 for minimum power.

Power is regulated by pushing the reverse valve (27) to forward

(F) or reverse (R) direction.

Place the socket over the subject nut and depress the trigger to

operate the wrench. Once a bolt or fastener is seated,

impacting for longer than five seconds will cause excessive

wear and damage to the impacting mechanism. If it takes

longer than five seconds to tighten your bolts or fasteners, we

recommend the use of a larger size impact wrench.

The spray pattern of the gun is variable from round to flat

with all patterns in between.