33

34

Learn more. Visit hunterindustries.com/golf

INLET VALVE REMOVAL

INLET VALVE REMOVAL

I

INLET VALVE REMOVAL –

G800 SERIES

With the main-line or sub-main depressurized, the riser assembly removed, the water extracted

from the body cavity, and the safety interlock feature disengaged, proceed with removal of the

G800’s white lower snap-ring and inlet valve as follows:

First, notice that close to each end of the white lower snap-ring there are two raised areas

(FIGURE 76). These two raised areas are used to remove the white lower snap-ring. Also notice

that the inlet valve has two posts protruding upward on top of the inlet valve. Take a moment

to note the orientation of these posts and how they nest within the white lower snap-ring.

Understanding this alignment and orientation will help later to confirm that the white lower snap-

ring has been properly seated after installation.

To remove the white lower snap-ring, use the 16” Needle-Nose Pliers Tool to grab the outer side

of the two raised areas near the ends of the white lower snap-ring. Next, squeeze the two raised

areas together with the tips of the 16” Needle-Nose Pliers Tool (FIGURE 78). This action will

collapse the white lower snap-ring. While holding the collapsed white lower snap-ring, pull the

16”needle-nose pliers up and out along with the white lower snap-ring (FIGURE 79).

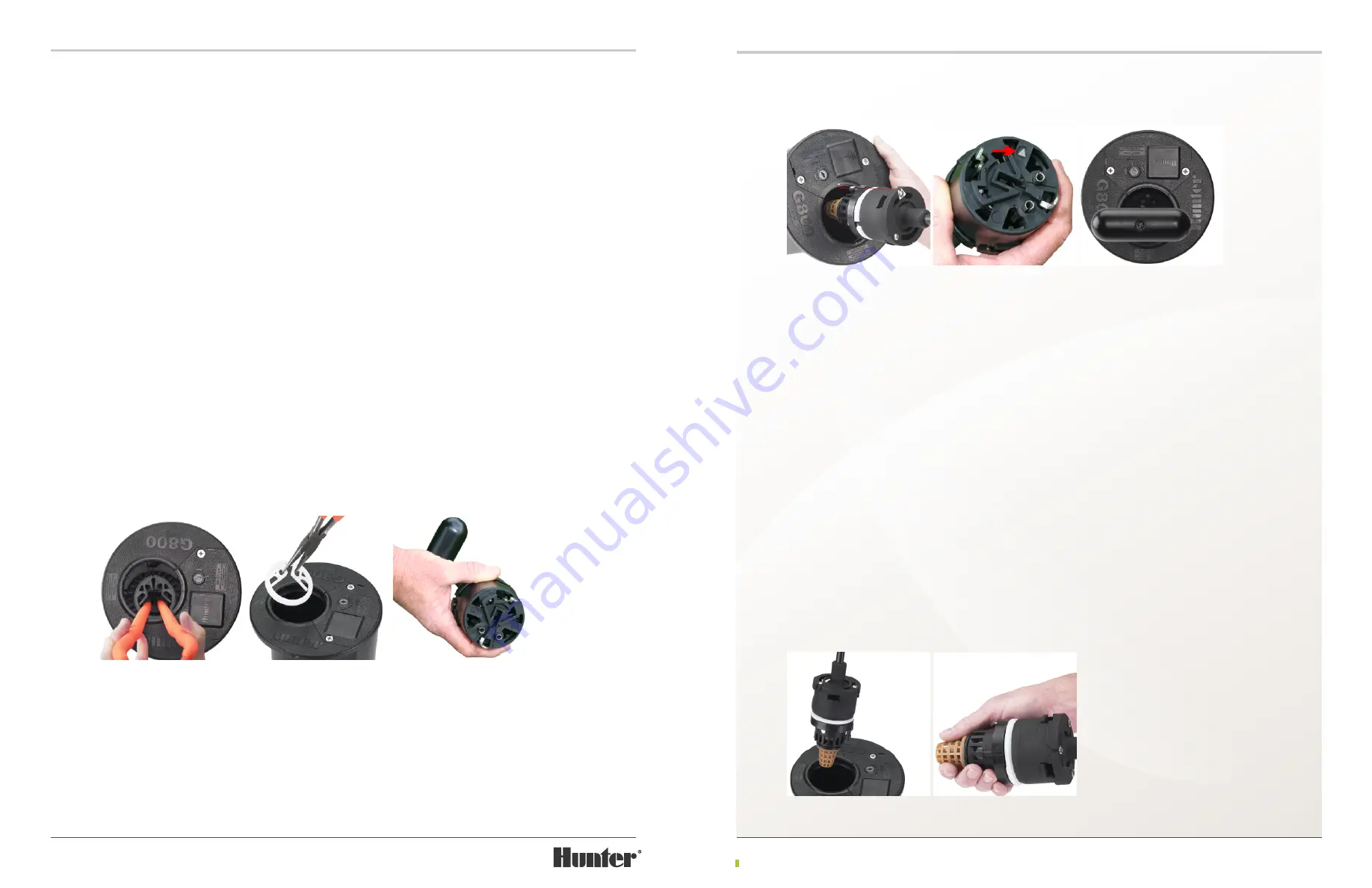

Inlet valve removal option 1

– Once the white lower snap-ring has been removed, the inlet valve

is released and is ready for removal. G800 Series inlet valves are removed from the body using

the G800 Valve Tool. Prior to using the tool, familiarize yourself with the individual features of the

G800 Valve Tool. First, notice there are two metal hooks at the bottom of the tool (FIGURE 80).

These hooks are used to grab/hook the inlet valve for removal from the rotor’s body. The black

plastic part of the G800 Valve Tool includes physical features that hold or nest the inlet valve to

the tool during inlet valve removal and installation.

In order to engage the inlet valve with the G800 Valve Tool properly, you must be familiar with the

pointing and alignment features on the tool’s black plastic part. First, look at the three retaining

screws on top of the tool. Next, find the screw that has a pointer arrow engraved around the head

of the screw (FIGURE 81). This pointer is used to indicate the direction and alignment that the tool

must have as it is inserted into the rotor’s body. A second pointer arrow is located directly below

on the underside of the G800 Valve Tool (FIGURE 82).

To remove the inlet valve, it is necessary to

align the pointer arrow on the G800 Valve Tool

with the alignment dot on the rotor’s flange.

The alignment dot is centered on the flange

compartment lid adjacent to (next to) the body

cavity opening (FIGURE 81). A second alignment

dot is located below the lid in case the flange

compartment lid has been removed. Align the

pointer arrow on the tool with the alignment

dot and lower the tool into the rotor’s body.

As the G800 Valve Tool is lowered into the

rotor’s body, recessed areas on the black

plastic part on the tool will engage vertical

rails inside the body wall (FIGURE 83). The

tool must engage these rails or the tool will

not align with the inlet valve below. Continue

pressing downward, compressing the spring

on the G800 Valve Tool. While holding the

tool down with the spring compressed, turn

the tool’s handle clockwise until it stops. Next,

release the spring’s compression by lifting the

handle slightly on the G800 Valve Tool. This

action hooks and locks the inlet valve to the

tool. Finally, pull upward on the tool’s handle to

remove the tool and inlet valve from the rotor’s

body (FIGURE 84).

Important: Take note of how the G800 Valve Tool nests with the attached inlet valve. This

will help later when attaching the inlet valve to the tool prior to inlet valve installation.

To disengage the inlet valve from the G800

Valve Tool, hold the inlet valve with one hand

and the tool with the other hand. Next, push the

tool’s handle toward the inlet valve to compress

the tool’s spring (FIGURE 85). While compressing

and holding the spring, rotate the tool’s handle

counter-clockwise to release the tool’s hooks

from the inlet valve.

Fig 78

Fig 79

Fig 78

Fig 79

Fig 80

Fig 81

Fig 82

FIGURE 78

FIGURE 79

FIGURE 80

Fig 80

Fig 81

Fig 82

Fig 83

Fig 84

Fig 85

Fig 80

Fig 81

Fig 82

Fig 83

Fig 84

Fig 85

Fig 83

Fig 84

Fig 85

FIGURE 81

FIGURE 84

FIGURE 82

FIGURE 85

FIGURE 83