Chengdu Huayuan Electric Equipment Co.,Ltd

LGK-40/63/100IGBT OPERATOR’S MANUAL

13

8.

Operation Caution

Before operation, operator must put on insulating shoes and wear insulating gloves & protection glasses. The earth line must be

connected reliably.

If to use contact arc striking method, firstly press down torch switch, then have nozzle contact workpiece edge quickly, this will

be beneficial for arc striking cutting. If it is difficult to strike arc, the gas pressure can be adjusted to lower limit.

The water in reducing valve and air compressor should be drained out frequently. The cutting speed should not be too fast, so that

it can avoid molten slag and arc reflection caused by incomplete cutting, but the cutting speed should not be too slow too, it will

have workpiece red-hot and affect cutting quality. When the cutting stops, firstly loosen torch switch, then lift up torch. To follow

above can have nozzle work life improved a lot.

The status of gas pressure, voltage, electrode and nozzle should be observed closely during cutting. Do not have electrode and

conductive tip short circuit caused by copper spraying after using up hafnium wire in electrode, and damage cutting torch. The

hafnium wire in each electrode is about 3mm in length. After nozzle aperture is enlarged, cutting quality and thickness will

decrease seriously, so the nozzle must be replaced immediately.

If the cutting seam is deviated seriously, the nozzle must be checked if it flanges and deviates. Or the nozzle and electrode must

be replaced. Notice: the roughness of cutting surface is related to cutting plate surface. If the plate surface is rough and not clear,

cutting moving is uneven, then the incision is big and surface quality decreases seriously.

The work life of electrode and nozzle is related to plate thickness and operation technology. Normally every electrode can keep

using for 1 hour continuously.

Maintenance

The cutter cannot be operated and placed in strong sunshine.

The cutter cannot be operated and placed in moist environment.

The vent hole should not be covered when the cutter is operated.

The cutter should be operated and placed in drafty environment.

The cutter casing should be opened once a year at least. Clean up the dust and metal scraps inside the machine by use of

compressed gas.

Check regularly if the cable insulation cover is damaged. If there is any damage, repair it or change it.

Check regularly if the electric connection is loose and then tighten it.

Drain out regularly the water and impurities from filtering reducing valve.

Notes: When maintaining the cutter, professional electrician is required to dismantle the power wire from

distribution box and open the machine casing.

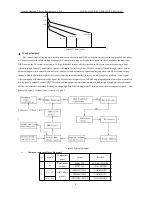

Cutting technology instruction

1.

The related main technical parameters

Cutting material and thickness

The selection of cutting technical parameters is based on the cutting material and thickness. If the material is thick, it should adopt

large current and nozzle with big aperture. For different material under the same thickness, the parameter should also be different.

Air flow Q

The arc voltage increases as the increase of air flow, that is, the arc power, the cutting speed, as well as the cutting capacity and

quality is improved accordingly. Because the arc compression level increases, the energy is more concentrated, the arc beam

temperature, the arc spraying speed, as well as the arc current impulsion increases. But overlarge current may cause the instability of

the plasma arc. Usually no change is made to air flow for one torch. But it can be adjusted a little when the cutting torch or cutting

thickness is different.

Cutting speed

The cutting speed is related with many parameters. The main parameters determining cutting speed include workpiece thickness,

cutting current, air flux and nozzle aperture. A proper drag is allowed during cutting. The cutting speed should be increased as much as

possible, but the incision quality must be guaranteed.

2.

Eliminate the cutting burr

Содержание LGK-63/100MA

Страница 18: ......