Operator's manual

M 824

51

EN

Fig.9a

A

9a

A No rim well

DANGER

When working on this tyre type, the

tyre, the rim or both may get damaged,

with the risk of the tyre exploding due

to pressure causing serious injuries

or even death. When mounting tyres

on this type of wheel, use the utmost

caution

.

European style high performance

wheels (asymmetrical curvature)

Some European wheels have very pro-

nounced curves on the rim edge, except

in the area of the valve hole. On this type

of wheel bead, breaking must be per-

formed in correspondence with the valve

hole and on the lower and upper side of

the wheel.

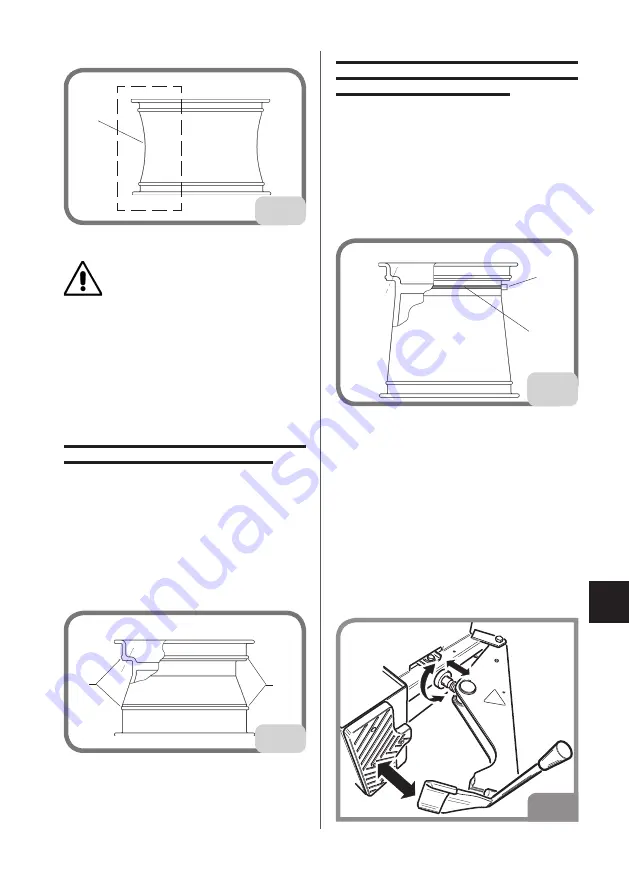

Fig.9b

A

B

C

9b

A Valve hole

B Slight curvature

C Pronounced curvature

Wheels for Corvette, BMW, Lam-

borghini and other wheels with "Low

pressure indicator system"

Some types of high performance wheels

are equipped with a pressure transmit-

ter secured to the rim with a belt on the

side opposite the valve hole. On this type

of wheel bead breaking must be done

initially in correspondence with the valve

hole, on both sides of the rim.

Fig.9c

A

B

C

9c

A Valve hole

B Transmitter

C Attachment belt

Bead breaking

- Fully deflate the tyre, removing the

valve.

- Adjust the opening of the bead breaking

shoe by turning the screw located on the

cylinder stem (fig.10).

10

Содержание M 824

Страница 16: ...Operator s manual M 824 53 EN 10 20 13 23 14 24 min 17 14...

Страница 28: ...Operator s manual M 824 65 EN 32...

Страница 29: ...66 Operator s manual M 824 33...

Страница 30: ...Operator s manual M 824 67 EN 34...

Страница 31: ...68 Operator s manual M 824 35...

Страница 32: ...Operator s manual M 824 69 EN STANDARD VERSION...

Страница 33: ...70 Operator s manual M 824 FS VERSION...

Страница 34: ...Operator s manual M 824 71 EN STANDARD VERSION AIR MOTOR...

Страница 35: ...72 Operator s manual M 824 FS VERSION AIR MOTOR...

Страница 36: ...Operator s manual M 824 73 EN Notes...

Страница 37: ...74 Operator s manual M 824 Notes...