10 of 24

Service Manual UK

Indesit

Company

English

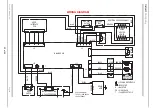

Control Module

The control module is located behind the right hand side panel and there is a service port behind the

plinth cover that allows attachment of a Computer to programme the EEPROM or test the control

module.

Contains the main processor and memory and EEPROM.

Controls the motor, heater and dryness levels using sensor in the drum and front and rear thermistors.

The control module can be programmed with the relevant eeprom file it the module is replaced, the

Eeprom file becomes corrupted or if an updated file becomes available.

The programming procedure can be found in Eeprom Writer Manual 5407177.

Door

A plastic moulded chassis with a glass bowl retained by plastic mouldings.

Door Switch

Normally open single pole microswitch activated by the door on closure. It is the first switch in the

electrical circuit and therefore its rating corresponds to the full load of the product.

Drum

Manufactured from Galvatite or steel/stainless steel in three pieces with a chrome or zinc plated steel

shaft at the rear. The three pieces are lock seamed together. The rear pressing has perforations to

allow air into the drum. The body has two removable equi-spaced plastic lifters used to tumble the

clothes. The front pressing has a large diameter flanged aperture through which the clothes are

passed into the drum. This flanged aperture supports the front of the drum on four lubricated bearing

pads fitted to the front air duct. A shaft running in a single bearing attached to the rear panel supports

the rear of the drum.

A strip type conductivity sensor is located in the front air duct. This is used by the electronics to sense

the resistance of the moisture in the clothes in the drum and determine their dryness level.

The drum comprises of a zinc-coated front and rear body. The rear of the drum is perforated to allow

the passage of air. Fixed to the rear pressing is a support shaft, which runs in a bearing located in the

rear panel of the dryer.

A drive pin and collar on the drum shaft prevents forward thrust during use. The large front flanged

aperture rotates on bearing pads.

Heater Unit

Consists of four coils wound on ‘mica’ supports, which are supported by ‘mica’ end insulators.

These end insulators fit into a steel pressing that also locates the rear thermal controls this is fixed by

screws to the rear cover, this pressing also forms air guides. The heater elements thermal controls,

thermistors and rear cover are supplied as an assembly and has a five-way connector provided to

interface with the electronic module. The heater has an upper and lower heater, the lower (static)

heater is permanently energised and the upper heater (dynamic) is cycled on and off by the control

module during a programme to maintain the correct temperature for the programme selected.