13

68-0049—2

VR8205; VR4205

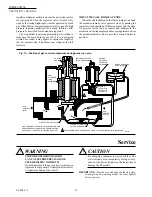

␣␣␣␣␣␣␣␣␣␣␣␣SERVICE

IF MAIN BURNER WILL NOT COME ON WITH

CALL FOR HEAT

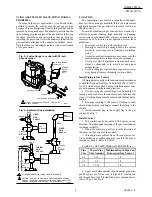

1. Confirm that gas control knob is in the ON position.

2. Adjust thermostat several degrees above room tem-

perature.

3. Using ac voltmeter, measure voltage across MV

terminals at gas control.

4. If no voltage is present, check control circuit for

proper operation.

5. If proper control system voltage is present, replace

gas control.

INSTRUCTIONS TO THE HOMEOWNER

FOR YOUR SAFETY, READ BEFORE LIGHTING

WARNING

IF YOU DO NOT FOLLOW THE

WARNINGS BELOW AND THE

LIGHTING INSTRUCTIONS EXACTLY, A

FIRE OR EXPLOSION CAN RESULT

WITH PROPERTY DAMAGE, PERSONAL

INJURY OR LOSS OF LIFE.

1. Before lighting, smell around the appliance

area for gas. If the appliance uses LP (bottled)

gas, be sure to smell next to the floor because

LP gas is heavier than air. If you smell gas,

immediately shut off the manual valve in the

gas piping to the appliance, or on LP, at the

tank. Do not try to light any appliance. Do not

touch any electrical switch or use the phone.

Leave the building and call your gas supplier.

If your gas supplier cannot be reached, call the

fire department.

2. Do not force the gas control knob on the appli-

ance. Use only your hand to turn the gas con-

trol knob. Never use any tools. If the knob will

not operate by hand, replace the control using a

qualified service technician. Force or attempted

repair can result in fire or explosion.

3. The gas control must be replaced if it has been

flooded with water. Call a qualified service

technician.

4. The gas control is a safety device. It must be

replaced in case of any physical damage such

as bent terminals, missing or broken parts,

stripped threads, or evidence of exposure to

heat.

IMPORTANT: Follow the operating instructions pro-

vided by the manufacturer of your heating appliance.

The information below will be of assistance in a

typical control application, but the specific controls

used and the procedures outlined by the manufac-

turer of your appliance may differ, requiring special

instructions.

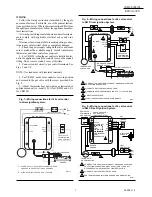

TO TURN ON FURNACE

STOP: Read the safety information above.

1. The lighting sequence on this appliance is automatic;

do not attempt to manually light the main burner.

2. If the furnace does not come on when the thermostat

is set several degrees above room temperature, set the

thermostat to the bottom of its range to reset safety control.

3. Remove burner access panel if provided on your

appliance.

4. Turn the gas control knob (Fig. 5) clockwise

to

OFF.

5. Wait five minutes to allow any gas in the combustion

chamber to vent. If you then smell gas in the appliance area

or near the floor in an LP installation, immediately shut off

the manual valve in the gas piping to the appliance, or on

LP, at the tank. Do not touch any electrical switch or use the

phone. Leave the building and call your gas supplier. If

your gas supplier cannot be reached, call the fire depart-

ment. Failure to do so may result in fire or explosion.

6. If you don’t smell gas, turn knob on gas control

counterclockwise

to ON.

7. Replace burner access panel.

8. Reset thermostat to desired temperature.

9. If burner does not come on when room temperature is

below thermostat setting, turn gas control knob to OFF and

contact a qualified service technician for assistance.

TO TURN OFF APPLIANCE

Turn gas control knob clockwise

to OFF.

!