68-0049—2

10

VR8205; VR4205

STARTUP AND CHECKOUT • MAINTENANCE • OPERATION

1. Turn off gas supply.

2. Set thermostat or controller above room temperature

to call for heat.

3. Watch for ignition spark or for glow at hot surface

igniter either immediately or following prepurge. See DI

module specifications.

4. Time the length of the igniter operation. See DI

module specifications.

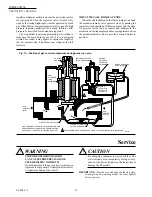

Operation

The VR8205;VR4205 gas controls provide ON-OFF

manual control of gas flow. In the OFF position, gas flow to

the main burner is mechanically blocked. In the ON posi-

tion, gas flows to the main burner under control of the

thermostat, the direct ignition (DI) module, and the two

automatic main valves.

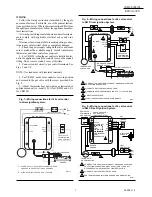

SYSTEM OPERATION WITH MODULE

When the thermostat calls for heat, the DI module is

energized. The module activates the first and second auto-

matic valves of the gas control, which allow gas to flow to

the main burner. At the same time, the DI module generates

a spark at the igniter-sensor to light the main burner.

The second automatic valve diaphragm, controlled by

the servo pressure regulator, opens and adjusts gas flow as

long as the system is powered. The servo pressure regulator

monitors outlet pressure to provide an even flow of gas to

the main burner. Loss of power (thermostat satisfied) de-

energizes the DI module and closes the automatic valves.

The system is ready to return to normal service when power

is restored through the thermostat.

If the igniter-sensor stops detecting a flame at the main

burner, the trial for ignition is restarted. On DI modules

with lockout timers, the automatic valves are de-energized

and ignition stops after the lockout period. On modules

without lockout timers, the trial for ignition continues

indefinitely.

If main burner flame is restarted successfully, operation

continues as described above. Gas control operation is

described in more detail below.

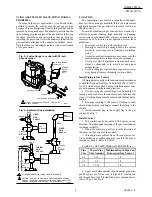

VALVE POSITION DURING THERMOSTAT OFF

CYCLE

The valve is positioned as shown in Fig. 10 when the:

• manual gas control knob is in the ON position.

• thermostat is not calling for heat.

The first automatic valve is closed. The second auto-

matic valve operator is de-energized, closing the channel to

the pressure regulator, and opening a channel to the under-

side of the second automatic valve operator valve dia-

phragm. The combination of spring pressure under the

second automatic valve diaphragm and lack of outlet pres-

sure holds the diaphragm firmly closed. Gas flow to the

main burner is blocked by both valves.

Regular preventive maintenance is important in applica-

tions that place a heavy load on systems controls, such as in

the commercial cooking and agricultural and industrial

industries because:

• In many such applications, particularly commercial

cooking, the equipment operates 100,000-200,000

cycles per year. Such heavy cycling can wear out the

gas control in one to two years.

• Exposure to water, dirt, chemicals and heat can dam-

age the gas control and shut down the control system.

The maintenance program should include regular check-

out of the gas control, see Startup and Checkout section,

and the control system as described in the appliance manu-

facturer literature.

Maintenance frequency must be determined individu-

ally for each application. Some considerations are:

• Cycling frequency. Appliances that may cycle 20,000

times annually should be checked monthly.

• Intermittent use. Appliances that are used seasonally

should be checked before shutdown and again before

the next use.

• Consequence of unexpected shutdown. Where the

cost of an unexpected shutdown would be high, the

system should be checked more often.

• Dusty, wet, or corrosive environment. Since these

environments can cause the gas control to deteriorate

more rapidly, the system should be checked more

often.

Gas valves exposed to high ammonia conditions; i.e.,

those used in greenhouses or animal barns, may fail in one

or two years. Contact your Honeywell sales representative

to request a gas valve with corrosion resistant construction.

The gas control should be replaced if:

• It does not perform properly on checkout or trouble-

shooting.

• The gas control knob is hard to turn.

• The gas controls is likely to have operated for more

than 200,000 cycles.

Maintenance

5. After the module locks out, open manual gas cock

and make sure no gas is flowing to the burner.

6. Set the thermostat below room temperature and wait

one minute.

7. Operate system through one complete cycle to make

sure all controls operate properly.