68-0049—2

12

VR8205; VR4205

OPERATION • SERVICE

regulator maintains outlet pressure at the preset step rate for

several seconds. Then the regulator valve is forced fully

open by the timing diaphragm, which is operated by bleed

gas. When the low pressure regulator is fully open, the high

pressure regulator maintains the desired full-rate outlet

pressure as described for the standard regulator.

The step model requires approximately 60 seconds to

reset once the main burner goes off. If it is reenergized

within 60 seconds, it may bypass or shorten the length of

the low pressure step. The burner may relight at the full

flow rate.

WHEN THE CALL FOR HEAT ENDS

When the call for heat ends, the first automatic valve and

the second automatic valve operator close, bypassing the

regulator(s) and shutting off the main burner and the pilot.

As pressure inside the gas control and underneath the

automatic valve diaphragm equalizes, spring pressure closes

the second automatic valve to provide a second barrier to

gas flow.

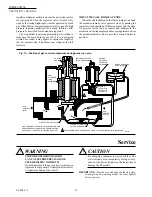

Fig. 11—Position of gas control components during burner on cycle.

Service

!

!

WARNING

FIRE OR EXPLOSION HAZARD

CAN CAUSE PROPERTY DAMAGE,

SEVERE INJURY OR DEATH

Do not disassemble the gas control; it contains no

replaceable components. Attempted disassembly

or repair may damage the control.

CAUTION

Do not apply a jumper across (or short) the valve

coil terminals, even temporarily. Doing so may

burn out the heat anticipator in the thermostat or

damage the DI module.

IMPORTANT: Allow 60 seconds after shutdown before

re-energizing step-opening model to assure lightoff

at step pressure.

FIRST

AUTOMATIC

VALVE

SOLENOID

CONTROL

KNOB

GAS

CONTROL

INLET

SECOND AUTOMATIC

VALVE OPERATOR

SECOND

AUTOMATIC

OPERATOR

SOLENOID

SECOND

AUTOMATIC

OPERATOR

VALVE DISC

SERVO PRESSURE

REGULATOR

GAS

CONTROL

OUTLET

SECOND AUTOMATIC

VALVE DIAPHRAGM

FIRST AUTOMATIC VALVE

NOTE: SECOND AUTOMATIC VALVE OPERATOR AND

SERVO PRESSURE REGULATOR SHOWN OUTSIDE

GAS CONTROL FOR EASE IN TRACING GAS FLOW.

SLOW-OPENING GAS CONTROL HAS A GAS FLOW RESTRICTOR IN THIS PASSAGE.

M9115

1

1