U2-S MODEL COMBINATION VIEWING HEAD AND SIGNAL PROCESSOR

32-00015—05

6

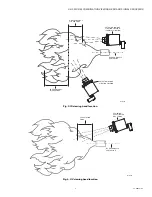

Fig. 5. Sighting opposed fired burners.

Mounting Accessories

1.

Cable assemblies for quick disconnect models are

listed below. All are ITC/CIC approved, and meet

IP67 at connector when properly installed.

• ASYU2S molded connector with 50 foot cable.

• ASYU2S-100 molded connector with 100 foot

cable.

• ASYU2-200 molded connector with 200 foot

cable.

• ASYU2-300 molded connector with 300 foot

cable.

2.

Fiber Optic System - The U2 models are compatible

with the Honeywell FASA Glass or Quartz fiber optic

extension. Refer to Honeywell manual 69-2683

3.

U2-S supports Modbus protocol. The system can be

monitored using user's hardware and software

and/or Honeywell FlameTool for PC or Honeywell

FlameTool for Panel (S7999). For detail refer to man-

ual 32-00001 and 32-00003.

4.

There are several mounting accessories available

from Honeywell. Please check with your sales person

for detail.

a. R-518-PT12 (Ultem Iso PT Adapter)

b. R-518-PT12L (Ultem Iso PT Adapter with lens)

c. R-518-CL12-PG (Purge Air Coupler 1" NPTM &

1/2" NPTF)

d. M-701-2 (Swivel Mount)

e. R-518-CL12-HTG (Locking Coupler).

OPERATION

Available sensors continuously convert flame radiation to

a magnitude displayed on the U2 display. The displayed

value described further as "flamecount" is the sum of all

active sensor readings.

If flame count is greater than the flame on setpoint for

longer than the time delay, a flame on condition is realized

and the flame relay contacts are closed. The flame relay

contacts remain closed until the flame count falls below

the flame off setpoint for longer than the flame failure

response time, at which a flame off condition is realized

and the flame relay contacts are opened. Periodic self

check performs fault detection, and if a fault is detected,

both the flame relay and self check relay contacts are

opened.

While File Input Select is low, file parameters defined at

Modbus register 40093 are used to determine flame relay

state. While file input select is high (+24V), file 1 parameter

settings are used to determine flame relay state.

File Select Output provides feedback to indicate the state

of the file input select. See chart below:

There are several parameter adjustments that permit

configuration of each sensor. .

A touch wheel located at the back of the viewing head

provides access to parameters for adjustment and

configuration. The configuration menu is simple and easy

to follow. Full character, 4-digit, scrolling LED displays are

visible in the dark or sunlight. Individual sensor LEDs

(model dependent 1, 2, or 3 total located below the

display) flash to indicate the output of each sensor (green

= UVTron, Blue = SSUV, Red = IR). The upper right green

self-check LED provides indication, and status of the self

check. The upper left red "Flame On" LED provides status

of the flame relay.

NOTE:

The number of LEDs are model dependent.

The touch wheel is designed like an iPod™ to allow for slow

or fast changes by moving a finger slower or faster around

the back glass. Alternatively, the user may tap

←

(-) or

→

(+) to make changes. Swirl finger at touchwheel > 360

degrees and release to enter the menu. Tap

ENTER/STORE to store selected data. Tap BACK to return

to the previous menu. Exiting all of the menus will display

the current flame count.

VIEWING HEAD

BURNER NOZZLE

NO. 1

NO. 1 FLAME

ENVELOPE

NO. 2 FLAME

ENVELOPE

VIEWING HEAD

BURNER

NOZZLE NO. 2

HIGH FREQUENCY

IR ZONE

LOW FREQUENCY

ZONE (LESS THAN

36HZ)

HIGH FREQUENCY

IR ZONE

M33287B

File Input Select Value

File Select Output Value

0V

0V

24V

24V