U2-S MODEL COMBINATION VIEWING HEAD AND SIGNAL PROCESSOR

3

32-00015—05

PF version

General

FM, CSA, CE (EN298), and EAC

Hazardous Location

CSA

CLASS I, DIVISION 1, GROUPS A, B, C, D

CLASS II, DIVISION 1, GROUPS E, F, G

CLASS III DIVISION 1 T6

Ex d IIC T6 Gb Ex tb IIIC T85°C Db

CLASS I, ZONE 1, AEx d IIC T6 Gb

ZONE 21 AEx tb IIIC T85°C Db

IECEx SIR 15.0068X Ex db IIC T6 Gb

Ex tb IIIC T85°C Db IP66

SIRA 15ATEX1192X Ex db IIC T6 Gb

Ex tb IIIC T85°C Db IP66

CAUTION

CAUTION

!

Possible Equipment Damage

The aluminum surface of the U2 may store an

electrostatic charge and become a source of

ignition in applications with a low (<30%) relative

humidity. Cleaning the surface should only be

done with a damp cloth.

CAUTION

CAUTION

!

Do not expose to acetone, gasoline, hexane, or

ethyl acetate. label is not approved for these

chemicals.

Wiring

See “Typical Installation Diagram.” on page 12.

*Note - pink wire unused, leave unconnected.

CAUTION

CAUTION

!

Check wiring before applying power to the

system to make sure it is in accordance with the

wiring chart. Incorrect wiring may result in

unsafe operation or damage to U2.

NOTES:

1.

For remote configuration and monitoring, refer

to Honeywell manuals for FlameTool for PC

(32-00001-01) and HMI S7999 Panel (32-

00003-01).

2.

A total of eight parameter files are available.

Files 2 through 7 may be accessed using Fla-

metools, and configured using Modbus regis-

ter 40093.

INSTALLATION

BELGIUM

Maxon International BVBA

Luchthavenlaan 16-18

1800 Vilvoorde, Belgium

Tel: 32.2.255.09.09

Fax: 32.2.251.82.41

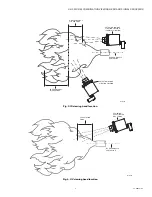

See “Typical Installation Diagram.” on page 12.

Installation should be carried out by a qualified engineer

and should meet all local standards and safety

requirements.

Hazardous location installations require the use of

ITC/CIC approved cable installed in cable tray for non-PF

models, and in metal conduit for -PF models. The cable

installation must conform to the latest revision of the

National Electrical Code, or Canadian Electrical Code for

Class I, Division 2 (non-PF models), or for Class I, Division

1 (-PF models).

WARNING

WARNING

WARNING

Approved CLI, DIV1 conduit seal must be

installed at PF model enclosure fitting for CLI,

DIV1 hazardous location use.

Non-PF models must be secured as follows: hand-tighten

the connector at viewing head until it can be turned no

more. Continue tightening the connector an additional

180 degrees using pliers, or similar tool. Verify that

connector cannot be loosened by hand.

Non-PF/

Color

Function

Connection

1-Red

Power 24 VDC

Connect to 22-26 VDC

To power supply

positive terminal

2-Purple

File Select Input, 0 or 1

To control output. >21V

input = file 1,

<16V = active file

defined at Modbus

register 40093(default

0).

3-Orange

mA output (+)

To current meter

positive

4-Blue

mA output (-)

To current meter

negative

5-Black

Power Supply Return (-) or 0 VDC

To Power Supply

negative terminal.

6-Yellow

Flame Relay (NO)

(power in)

To flame/fault relay

power source

7-Green

Fault Relay (NO) (fault output)

To fault monitoring of

burner control system

8-Grey

Flame Relay (NO)

(safety output)

To burner control

system

9-Tan

File Select Output, 0 or +24V

output. Feedback for system

controlling file input select.

To burner control

system. 0V = File Select

Input is low, or +24V if

FileSelect Input is high.

10-White

+RS485 Modbus

To

11-Drain

Cable Overall Shield

To Earth Ground

12-Brown

-RS485 Modbus

To Modbus -

Non-PF/

Color

Function

Connection