SV9501/SV9502/SV9601/SV9602 SMARTVALVE

TM

SYSTEM CONTROL

5

69-1270—3

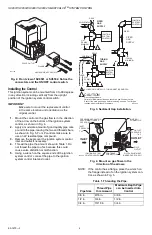

Fig. 5. Use a moderate amount of pipe compound.

Connecting the Pilot Gas Tubing

NOTE:

1.

The pilot tubing provides the SmartValve

TM

system’s flame sense current path. Make

sure the connections are clean and tight.

2.

Do not make sharp bends or deform the

tubing. Do not bend tubing at the ignition

system control after the compression nut is

tightened, because this can cause gas

leakage.

1.

Cut the tubing to the desired length.

2.

Bend the tubing as necessary for routing to the pilot

burner.

3.

Square off and debur the end of the tubing.

4.

Unscrew the brass compression fitting from the pilot

outlet.

5.

Slip the fitting over the tubing and out of the way.

6.

Push the tubing into the pilot gas outlet.

7.

Tap the outlet end of the control.

8.

Remove and discard the old fitting.

9.

While holding tubing all the way in, slide the new fit-

ting (included with the new SmartValve

TM

) into place

and begin thread until finger tight as shown in Fig. 7.

10.

Tighten fitting one more full turn with the wrench.

Do not overtighten.

11.

Connect the other end of the tubing to the pilot

burner as described in the instructions supplied with

Q3450 or Q3480 pilot hardware.

Wiring

Follow the wiring instructions supplied by the appliance

manufacturer if available. Otherwise, use the following

general instructions.

NOTE:

1.

In most cases, connect the wiring by plugging

the appliance wiring harness connector into

the SmartValve

TM

. Use the supplied exten-

sion harness if necessary.

2.

Where the general instructions are different

from the appliance manufacturer’s instruc-

tions, use the appliance manufacturer’s

instructions.

Fig. 6. Proper use of wrench on ignition system control with and without flanges.

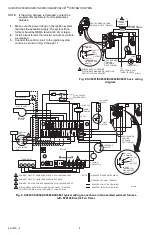

Fig. 7. Tighten new fitting and nut.

Always use a new compression fitting.

CAUTION

Equipment Damage Hazard.

Electrostatic discharge can short equipment

circuitry.

Disconnect the power supply before making wiring

connections.

IMPORTANT

All wiring must comply with applicable electrical

codes and ordinances.

TWO

IMPERFECT

THREADS

IGNITION

SYSTEM

CONTROL

THREAD PIPE THE AMOUNT

SHOWN IN TABLE FOR INSERTION

INTO IGNITION SYSTEM CONTROL

APPLY A MODERATE AMOUNT OF

PIPE COMPOUND ONLY TO PIPE

(LEAVE TWO END THREADS BARE).

M3344

PIPE

APPLY WRENCH FROM TOP OR

BOTTOM OF IGNITION SYSTEM

CONTROL TO EITHER SHADED AREA

WHEN FLANGE IS NOT USED

APPLY WRENCH

TO FLANGE ONLY

WHEN FLANGE IS USED

M7928

IGNITION SYSTEM CONTROL

TIGHTEN NUT ONE TURN

BEYOND FINGER TIGHT

FITTING BREAKS OFF AND CLINCHES

TUBING AS NUT IS TIGHTENED

TO PILOT

BURNER

M3346