SV9501/SV9502/SV9601/SV9602 SMARTVALVE

TM

SYSTEM CONTROL

69-1270—3

12

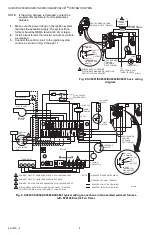

Fig. 14. SV9501/SV9502/SV9602/SV9601 SmartValve

TM

Sequence of Operation.

TROUBLESHOOTING

The attached flowcharts provide specific troubleshooting

information for the SV9500, SV9501 and SV9502/

SV9600, SV9601, SV9602 products. These charts assist

the field technician to analyze appliance operation

difficulties.

CAUTION

Equipment Damage.

Can damage connectors on wiring harness.

1.

Proper troubleshooting requires measurement

of voltage and resistance with a volt/ohm meter.

2.

Use proper size probes and appropriate testing

techniques to assure good test information

without damaging the control terminals,

connectors or wiring harness.

Use the following basic troubleshooting procedure.

1.

Review this information carefully prior to going to

the job site.

2.

Identify the specific SmartValve

TM

(SV9500,

SV9501, SV9502, SV9600, SV9601, SV9602).

3.

Make sure the Q3450/Q3480 HSI element is good.

4.

Disconnect the HSI element from the SmartValve

TM

.

5.

Using a multimeter, measure the HSI element room

temperature resistance. It should be less than 10

ohms.

6.

Make sure the SmartValve

TM

switch (knob if

SV9500/SV9600) is in the ON position (unless

directed otherwise in the Troubleshooting

flowchart).

7.

Make sure the appliance call for heat function

provides proper inputs to the SmartValve

TM

through

the 2X2 power connector. (Measure with voltmeter

on the ac scale.)

8.

Follow the Operating Sequence and

Troubleshooting flow charts as shown in Fig. 13 and

15 for the installed SmartValve

TM

SV9500/SV9600

to make sure replacement is necessary.

9.

Follow the Operating Sequence and

Troubleshooting flow chart in Fig. 14 and 16 for the

replacement SV9501/SV9502/SV9601/SV9602

SmartValve

TM

.

NOTE: The HSI element action for SV9501/SV9502/

SV9601/SV9602 is different from the HSI

element action for SV9500/SV9600. For

SV9500/SV9600, the element is on continuously

during a call for heat until shortly after the pilot

flame is detected, the main valve energizes and

the element turns off. For SV9501/SV9502/

SV9601/SV9602, the call for heat generates a

90-second “trial for pilot ignition.” If no pilot flame

is sensed, it retries after a five minute delay. The

element cycles off and back on once during the

trial for pilot ignition.

APPLY 24 VAC TO APPLIANCE

THERMOSTAT CALLS FOR HEAT

PREPURGE (SV9502/SV9602 ONLY)

FLAME SIGNAL DETECTED?

INTERNAL CHECK OKAY?

• PILOT VALVE OPENS

• IGNITER POWERED

PILOT LIGHTS AND FLAME IS SENSED

DURING TRIAL FOR IGNITION?

• IGNITER OFF

• MAIN VALVE OPENS

FLAME SIGNAL LOST?

ELECTRONIC FAN TIMER (EFT) OUTPUT ENERGIZES

THERMOSTAT CALL FOR HEAT ENDS

• MAIN AND PILOT VALVES CLOSE

• EFT OUTPUT DE-ENERGIZES

• MAIN AND PILOT VALVES CLOSE

• EFT OUTPUT DE-ENERGIZES

FIVE-MINUTE

RETRY DELAY

• WAIT FOR FLAME SIGNAL TO DISAPPEAR.

• PILOT VALVE/IGNITER REMAIN OFF

• PILOT VALVE CLOSES

• IGNITER OFF

FLAME LOST MORE THAN FIVE TIMES

IN ONE CALL FOR HEAT?

START

PREPURGE/

SYSTEM

CHECK

TRIAL

FOR

IGNITION

MAIN

BURNER

OPERATION

END

THREE-SECOND FLAME

FAILURE RECYCLE DELAY

NO

NO

NO

NO

NO

YES

YES

YES

YES

YES

M17144A

SV9501/SV9502/SV9601/SV9602 SmartValve® FAMILY SEQUENCE OF OPERATION

IGNITER WILL TURN OFF ABOUT 30 SECONDS INTO THE TRIAL FOR IGNITION IF THE PILOT FLAME HAS NOT LIT. IT WILL TURN BACK

ON FOR THE FINAL 30 SECONDS OF THE 90 SECOND TRIAL FOR IGNITION. THE PILOT VALVE WILL BE ENERGIZED DURING THE

ENTIRE TRIAL FOR IGNITION. THIS IS NORMAL OPERATION FOR THIS GAS IGNITION SYSTEM.

1

1