39

EN2R-9031 0402R15-NE

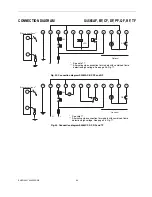

APPLICATION NOTE S4565DF, TF WITH EXTERNAL MAIN BURNER INTERRUPT

Fig. 47. Connection diagram S4565DF, TF with external main burner interrupt in fan assisted applications

External main burner interrupt

Maximum open contact voltage 24 V

Maximum current 15 mA

A low voltage relay is suitable.

An opto coupler e.g. CNY17-3 is also possible

A flame indicating series LED (see Fig. 49.) will conduct

minimal 0.85 mA if the contact is open and will conduct

minimal 3.5 mA if the contact is closed.

Suffix DF and TF in fan assisted applications (see Fig. 48.)

When there is a call for heat the fan starts running through

the no air position of the air proving switch after a self check

period (T

c

) plus a waiting period (T

w*

) (* = The safety time

starts after fan is switched on).

When sufficient air flow is proven by the air proving switch,

the built-in igniter and pilot gas valve are switched on.

The ignition spark ignites pilot gas and resulting flame is

detected by the flame rod.

Ignition is switched off after a predetermined extended

ignition time T(

ext

) and flame establishment and then the

main valve is switched on.

If flame is not established within the safety time (T

s

), the

ignition control locks out.

If the flame is lost during normal run, the ignition control

repeats start sequence.

If no air is proven by the air proving switch within the safety

time (T

s

), the ignition control locks out.

If the internal main burner interrupt is activated (relay contact

opened or opto transistor de-activated) the main valve drops

off, but the pilot flame stays present.

Suffix DF and TF in atmospheric applications (see Fig. 50.)

When there is a call for heat ignition starts immediately after

the self check period (T

c

) plus a waiting period (T

w

).

L

N

Side connections**

LM

RS

Optional

*

CNY 17-3

P

22 K

12

11

10

9

8

7

6

5

4

3

2

1

*

See note 17.

** Alternative side connection for models with combined flame

detection/high voltage. See page 56. Fig. 71.