10

Applicator Interface Kit Installation Guide

OUT Signals Specification

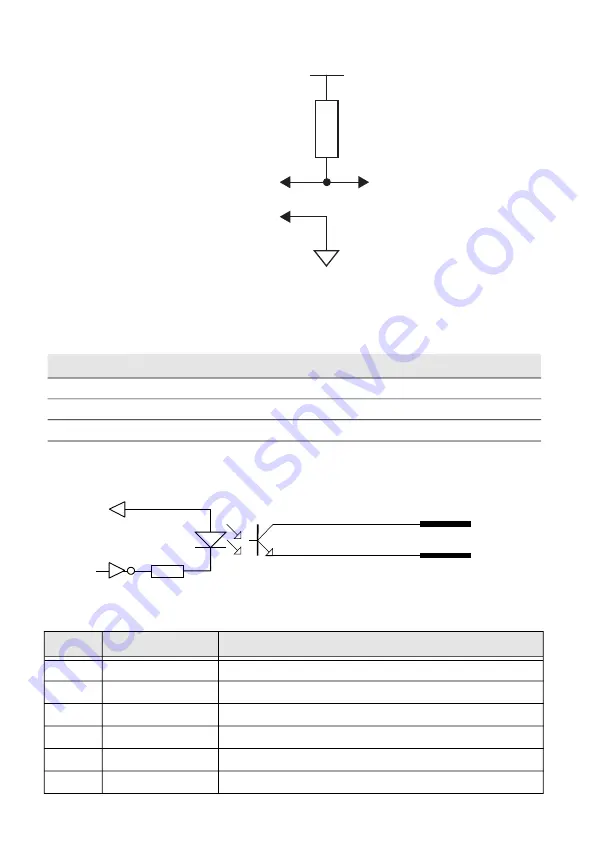

Simplified schematic of a digital IN port

OUT Signals Connector Configuration

Signal

Description

Max.

Vceo

Collector-Emitter breakdown voltage

35V

Veco

Emitter-Collector breakdown voltage

6V

Ic

Collector Current

15mA

Pin

Signal

Description

20

RibbonLow_C

Ribbon Low Collector Opto Out Channel

5

RibbonLow_E

Ribbon Low Emitter Opto Out Channel

35

Error_C

Error Collector Opto Out Channel

21

Error_E

Error Emitter Opto Out Channel

6

EndPrint_C

End Print Collector Opto Out Channel

36

EndPrint_E

End Print Emitter Opto Out Channel

Collector Pins:

6, 8, 20, 22, 24, 35, 37, 39

Emitter Pins:

5, 7, 9, 21, 23, 25, 36, 38

V+

V-

Output

R

VCC

OUTc

OUTa