AND ADJUSTMENT PROCEDURES FOR HONEYWELL

OR MP-953F PNEUMATIC OPERATORS USED ON

HUMIDIFIERS

II.

INSTALLING THE PNEUMATIC OPERATOR

After necessary repairs have been made, perform the

following steps to install the operator.

1.

2.

3.

4.

5.

6.

7.

a.

10.

Press down the valve stem (16) so

that the valve is

completely

closed.

Adapter

If the stem nut (17) and stem

Nut

adapter (17A) were not removed

---Stem

during

repairs,

check

the

adjustment shown

in Figure 2.

Adjust as required.

surface

If the stem nut (17) and stem

for

Operator

adapter (17A) were removed during

-Humidifier

repairs,

turn them onto the stem

and adjust as shown in Figure 2.

*With valve in closed position

Assemble the yoke assembly (36) and

Figure 2.

stem adapter (17A) in the following

manner.

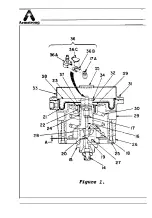

Hold the bearing (36B) in the orientation shown in

Figure 1 (flat side down, depression up).

Slide

the bearing into the groove of the stem adapter

Place the spring (36C) on top of the stem adapter

and bearing

(36B) with the longer tabs

pointed downward toward the notches in the sides

of the bearing.

c)

Slide the yoke (36A) over the spring

bearing

and stem adapter (17A) until the

short tabs of the spring snap into place on both

sides of the yoke.

Center the yoke over the stem

(16)

l

Place the operator over the yoke assembly (36) and

lower the operator onto the bonnet (15).

Hold the operator to prevent it from turning.

Insert a

screwdriver into the slot in the top of the yoke (36)

and turn counterclockwise until the operator base (26)

contacts the mating surface of the bonnet (15).

Tighten

two set screws (27).

Load the stem by turning the yoke (36) clockwise until

the spring cup (28) is from

to

inch above the

operator base (26).

(Dimension

in Figure 1).

Install the operator plug (35) in the top of the

9530 or close the access plate on the top of the

953B or MP-953F.

Turn on the steam to the humidifier.

Connect the air line to the operator and turn on the

instrument air.

Make any necessary adjustments.

2

Содержание MP953B

Страница 2: ...36 36 34 3g 23 37 Ad y p L _ 33 I 14 ...