W

innox · Edition 12.20

EN-14

no

X

and excess air

no

X

emission data is given for:

– Ambient combustion air (~70°F, 21°C)

– Less than 1000°F (540°C) firing chamber

– Minimal process air velocity

– Low fire input adjusted to minimum input On-Ratio, see page

– Neutral chamber pressure

emissions from the burner are influenced by:

– Chamber conditions

– Fuel type

– Firing rate

– Ratio regulator adjustments

– Combustion air temperature

CO emission is largely influenced by chamber conditions.

Contact your Honeywell representative for an estimate of CO emission

on your application.

0

10

20

30

40

50

60

0

100

200

300

400

500

700

0

30

60

90

120

150

180

600

NO

X

Emission (On ratio)

NO

X

ppm @ 3% O

2

NO

X

- Naturel gas

Input (kW)

Input (kBtu/h)

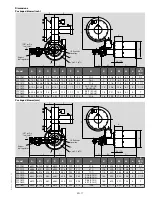

WX0050

0

100

150

200

0

100

200

300

400

500

700

0

30

60

90

120

150

180

50

600

Control and operation curve

% Excess air

Input (kW)

Typical Ratio Control

Input (kBtu/h)

WX0050

0

0

200

400

600

800 1000

1200

0

60

120

180

240

300

360

10

20

30

40

50

NO

X

Emission (On ratio)

NO

X

ppm @ 3% O

2

Input (kW)

NO

X

- Naturel gas

NO

X

- Propane/Butane

Input (kBtu/h)

WX0100

0

0

200

400

600

800

1000

1200

0

60

120

180

240

300

360

20

40

60

80

100

120

140

160

Control and operation curve

% Excess air

Input (kW)

Typical Ratio Control

Input (kBtu/h)

WX0100

0

10

20

30

40

50

60

70

0

400

800

1200

1600

2000

2400

0

120

240

360

480

600

720

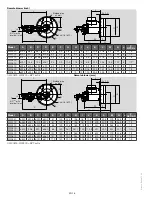

NO

X

Emission (On ratio)

NO

X

ppm @ 3% O

2

Input (kW)

NO

X

- Naturel gas

NO

X

- Propane/Butane

Input (kBtu/h)

WX0200

0

0

400

800

1200

1600

2000

2400

0

120

240

360

480

600

720

20

40

60

80

100

120

140

160

Control and operation curve

% Excess air

Input (kW)

Typical Ratio Control

Input (kBtu/h)

WX0200

0

0

0

200

400

600

800

1000

1200

600

1200

1800

2400

3000

3600

10

20

30

40

50

NO

X

Emission (On ratio)

NO

X

ppm @ 3% O

2

Input (kW)

NO

X

- Naturel gas

NO

X

- Propane/Butane

Input (kBtu/h)

WX0300