W

innox · Edition 12.20

EN-10

sPARe PARts

The web app PartDetective for selecting spare parts is available at

www.adlatus.org.

AssIstAnCe In tHe eVent oF MALFUnCtIon

? Problem

!

Possible Cause

• Solution

? start-up sequence runs but burner does not light.

!

No ignition: There is no power to the ignition transformer.

• Restore power to the ignition transformer.

!

No ignition: Open circuit between the ignition transformer and

the igniter.

• Repair or replace the wiring to the igniter.

!

No ignition: The igniter needs cleaning.

• Clean the igniter.

!

No ignition: The igniter is not correctly grounded to the burner.

• Clean the threads of the igniter and the burner.

note:

Do not apply grease to the thread of the igniter.

!

No ignition. Igniter insulator is broken. Igniter is grounding out.

• Inspect the igniter. Replace if broken.

!

Igniter grounds out, igniter is bent.

• Inspect ignitor by removing nozzle and rear cover. Check if

gaps exist, readjust if needed.

!

Not enough gas. The gas pressure into the ratio regulator is too

low.

• Check the start-up setting. Measure the gas pressures and

adjust where necessary.

!

Not enough gas. The impulse line to the ratio regulator is leak-

ing.

• Repair any leaks.

!

Not enough gas. The adjustable orifice valve is not open far

enough.

• Adjust bypass or low fire gas.

!

Not enough gas. Start gas solenoid valve does not open.

• Check the solenoid valve coil for proper operation. Replace

it if necessary.

!

Not enough gas. Gas valve does not open.

• Check the wiring to the automatic gas shutoff valve. Check

the output from the flame safeguard. Open manual gas cock.

!

Not enough gas. Ratio regulator is incorrectly set.

• Adjust the ratio regulator to the proper setting.

!

No flame signal. Broken flame rod and/or dirty UV scanner

lens.

• Inspect and clean sensor. Replace if necessary.

!

Too much gas. Gas butterfly valve too far open.

• Check for proper setting.

? the low fire flame is weak or unstable.

!

Not enough gas flowing to the burner.

• Adjust the ratio regulator or bypass fuel adjustable orifice

valve to increase the gas flow.

!

Not enough air.

• Check for proper blower rotation. Check air filter for block-

age. Compensate for chamber by opening the low fire air

butterfly valve position.

? the burner goes out when it cycles to high fire.

!

Not enough gas pressure into the ratio regulator.

• Check the start-up settings. Measure the gas pressures and

adjust them where necessary. Check for valve train pressure

loss.

!

Loading line to the ratio regulator is leaking.

• Repair the leak in the loading line.

!

Not enough gas flowing to the burner.

• Adjust the ratio regulator to increase the gas flow.

!

Fuel bypass line is not set correctly.

• Set fuel bypass pressure per technical data. More informa-

tion can be found here: page 10 (Technical data). Addi-

tional minor adjustments to the fuel bypass ALO valve may

be required to achieve a stable flame through the transition

between low and high fire.

? the burner is erratic and does not respond to adjust-

ment.

!

Internal damage to the burner. Some parts inside the burner

are loose, dirty or burned out.

• Contact Eclipse for further information.

? the burner is unstable or produces soot, smoke, or ex-

cessive carbon monoxide.

!

The air/gas ratio is out of adjustment.

• Measure all the gas pressures and air pressures. Compare

these pressures to the documented initial start-up settings

and adjust them where necessary.

? the burner cannot achieve full capacity.

!

Air filter is blocked.

• Clean or replace the air filter.

!

Gas pressure going into the ratio regulator is too low.

• Adjust the gas pressure.

? Cannot initiate a start sequence.

!

Air pressure switch has not made contact.

• Check air pressure switch adjustment. Check air filter. Check

blower rotation. Check outlet pressure from blower.

!

High or low gas pressure switch has activated.

• Check incoming gas pressure. Adjust gas pressure if neces-

sary. Check pressure switch setting and operation.

!

Malfunction of the flame safeguard system (e.g. shorted-out

flame sensor or electrical noise in the sensor line).

• Have a qualified electrician troubleshoot and correct the

problem.

!

No power to the control unit.

• Have a qualified electrician troubleshoot and correct the

problem.

!

Main power is off.

• Be sure the main power to the system is switched to the

“On” position.

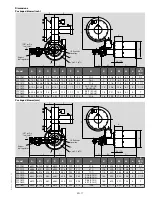

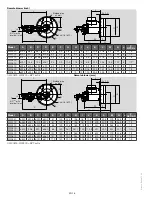

teCHnICAL DAtA

Input packaged blower

All information is based on laboratory testing. Different chamber

conditions will affect the data.

Eclipse reserves the right to change the construction and/or config-

urations of our products at any time without being obliged to adjust

earlier supplies accordingly.