LYNX BACNET PROGRAMMABLE, VAV/UNITARY CONTROLLERS – PRODUCT DATA

EN0Z-0959GE51 R0615

8

1. Find an unused MAC address on the MS/TP network to

which the LYNX controller connects.

2. Locate the DIP switch bank on the LYNX for addressing.

This is labeled “MAC Address.”

3. With the LYNX Controller powered down, set the DIP

switches for the MAC Address you want. Add the value of

DIP switches set to ON to determine the MAC address.

See Table 3. For example, if only DIP switches 1, 3, 5,

and 7 are enabled, the MAC address would be 85 (1 + 4 +

16 + 64 = 85).

NOTE:

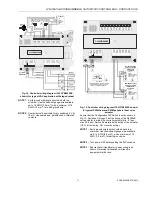

See Fig. 12 for DIP switch orientation and arrange-

ment.

Table 3. DIP switch values for MS/TP MAC address

DIP

7 6 5 4 3 2 1

VALUE

64 32 16 8 4 2 1

Setting the Device Instance Number

The Device Instance Number must be unique across the

entire BACnet system network because it is used to uniquely

identify the BACnet devices. It may be used to conveniently

identify the BACnet device from other devices during

installation. The LYNX controller’s Device Instance Number is

automatically set when it is added to a WEBStation-AX

project.

The Device Instance Number can be changed by the user,

which may be necessary when integrating with a third party or

when attempting to replace an existing controller and it is

desired to maintain the existing Device Instance Number.

To edit the Device Instance Number using WEBs AX:

1. Identify an unused Device Instance Number on the

BACnet Network, in the range of 0 - 4194302.

2. Open the LYNX BACnet Device Mgr View

a. Double click on the BACnet Network located in the

navigation tree.

b. Select the LYNX controller to be modified.

c. Click on the Edit button.

d. Enter an unused value in the Device ID field.

e. Select OK

3. Right click on the LYNX Controller and select “Actions >

Write Device Instance” to complete the update.

Termination Resistors

Matched terminating resistors are required at each end of a

segment bus wired across (+) and (-). Use matched precision

resistors rated ¼ W ±1% / 80…130

Ω

. Ideally, the value of the

terminating resistors should match the rated characteristic

impedance of the installed cable. E.g., if the installed MS/TP

cable has a listed characteristic impedance of 120

Ω

, install

120

Ω

matched precision resistors.

NOTE:

LYNX controllers do not provide network biasing.

Shield Terminating

Following proper MS/TP cabling shield grounding procedures

is important to minimize the risk of communication problems

and equipment damage caused by capacitive coupling.

Capacitive coupling is caused by placing MS/TP cabling close

to lines carrying higher voltage. The shield should be

grounded on only one end of the MS/TP segment (typically,

on the router end). Tie the shield through using the SHLD

(terminal 4) on the LYNX Controller.

Sylk™ Bus

Sylk is a two-wire, polarity-insensitive bus that provides both

18 Vdc power and communications between a Sylk-enabled

sensor and a Sylk-enabled controller. Using Sylk-enabled

sensors saves I/O on the controller and is faster and cheaper

to install since only two wires are needed and the bus is

polarity-insensitive. Sylk sensors are configured using the

latest release of the LYNX Tool for COACH

AX

.

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

9

9

9

ADD APPROPRIATE TERMINATION RESISTOR

BETWEEN BAC+ BAC- TERMINALS.

SHI

E

L

D

SHI

E

L

D

SHI

E

L

D

B

AC +

B

AC +

B

AC +

BA

C -

BA

C -

BA

C -

Fig. 11. Termination modules (BACnet MS/TP daisy chain

connections)

Wiring Details

Each controller is shipped with the digital outputs, which

switch the 24 Vac to the load (high side).

The three analog outputs (AO) are used to control modulating

heating, cooling and economizer equipment. Any AO may be

used as a digital output, as follows:

False (0%) produces 0 Vdc (0 mA)

True (100%) produces the max. 11 Vdc (22 mA)

The wiring connection terminals described in Table 4 are

shown in Fig. 12.

IMPORTANT

If the controller is not connected to a good earth

ground, the controller's internal transient protection

circuitry is compromised and the function of protecting

the controller from noise and power line spikes cannot

be fulfilled. This could result in a damaged circuit

board and require replacement of the controller. See

installation diagrams for specific wiring.

All controllers have terminal arrangements similar to the

example shown in Fig. 12 as described in Table 4.