CHYBA! POMOCÍ KARTY DOMŮ POUŽIJTE U TEXTU, KTERÝ SE MÁ ZDE ZOBRAZIT, STYL

ÜBERSCHRIFT 1.

HOLZMANN Maschinen Austria

www.holzmann-maschinen.at

Seite 38

Metalldrehbank/Metal turning lathe ED1000F

MAINTENANCES AND SERVICING

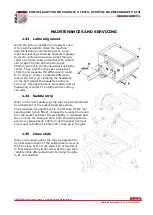

1.33

Lathe alignment

When the lathe is installed and ready for use,

it is recommended to check the machine

alignment before commencing work. Align-

ment and leveling should be checked regularly

to insure continued accuracy. Adopt this pro-

cedure as follow: take a steel bar with a diam-

eter of appr. 50mm and length of appr.

200mm. span it in the chuck without using the

center. Then cut off a chip over a length of

150mm and measure the difference in A and

B. In order to correct a possible difference,

loosen the screw (J) clamping the headstock

on the bed. Adjust the headstock with set-

screw (s). Repeat the above procedure until all

measuring is correct. The lathe will be cutting

correctly.

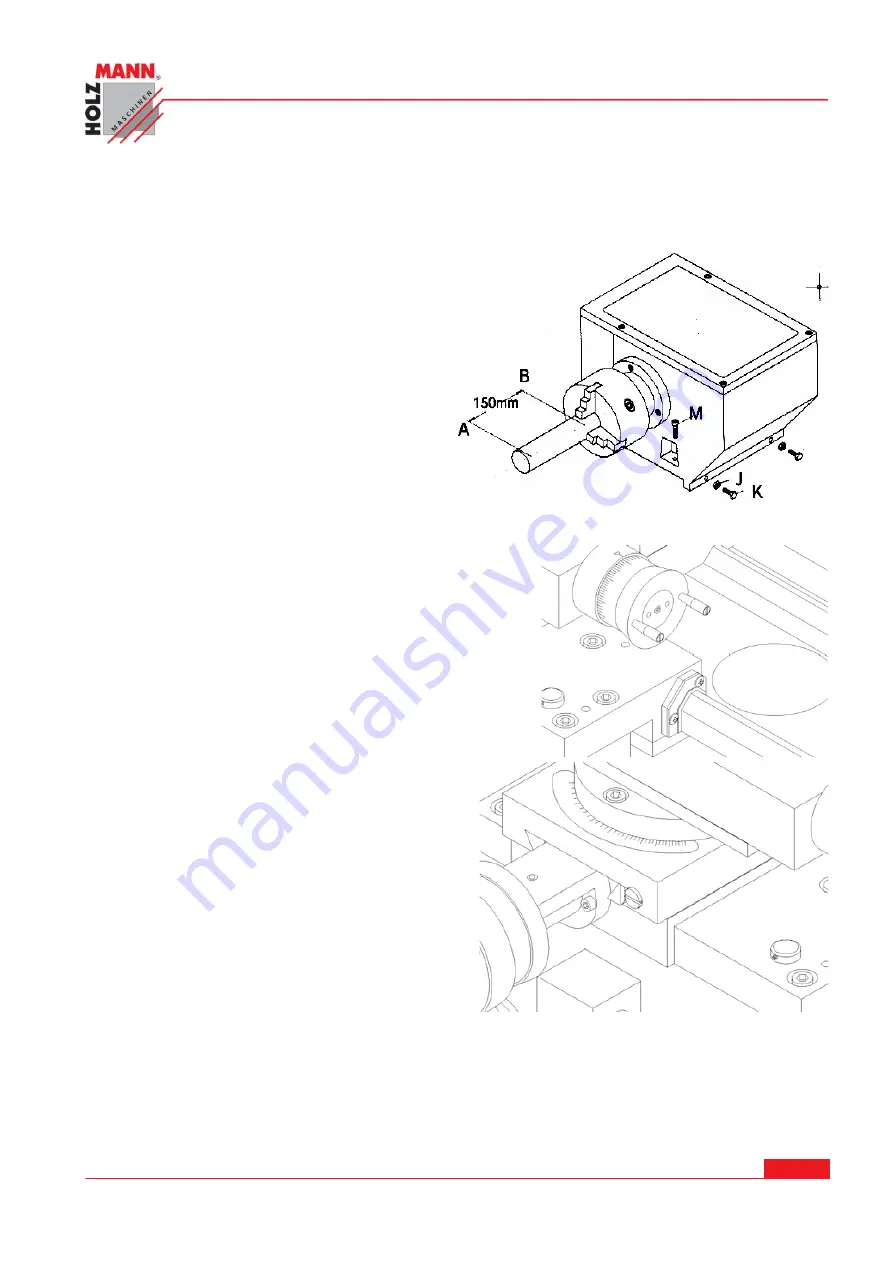

1.34

Saddle strip

Wear on the rear saddle gig strip may be accommodated

by adjustment of the socket head set screws.

The procedure for adjustment is to first take off the rear

splash guard (when fitted), release the hexagon nuts and

turn the socket head set screws slightly in clockwise and

the re-clomp the hexagon nuts. Care should be taken to

avoid over adjustment, α45°turn at the socket head set

screw approximately 0.125(0.005”) take up in the gibe.

1.35

Cross slide

Wear on the taper-gibe strip may be adjusted for

by clockwise rotation of the slotted head screw on

the front face of the cross slide. The procedure is

to first slacken the similar screw at the rear then

retighten this after adjustment to clamp the gibe

in its new position.