3.2

Collector Piping

The recommended flow rate for each collector is 0.025+/-.005 GPM/ft2. Consult the

chart below to determine the proper pipe size for different collector areas. Use only

metal pipe in the collector loop. Either type L or M copper is satisfactory, since the

piping is operated only at atmospheric pressure. The supply and return pipes are the

same size.

Table 3.2 Collector Circuit Pipe Sizing

Area of Collectors

Pipe Diameter

20-60 ft2

1/2 (3/4 in. recommended)

80-240 ft2

3/4 in.

240-400 ft2

1 in.

For collector piping runs longer than 50 feet one way, use the next pipe size. For roof

penetrations in residential type construction, use neoprene roof flashing boots made for

vent pipes. The hole diameter should be the outside diameter of the pipe insulation,

usually 2-1/2 - 3 inches.

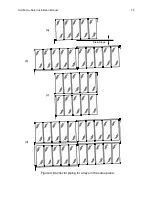

The piping arrangement for the collector array must follow these rules

1. water enters the collector array from the lowest corner.

2. water exits the collector array from the highest corner.

3. the water from all collectors must rise to a common high point before

it is allowed to drain back to the tank.

4. there can be no traps in the lines from the collectors to the tank.

The rules assure that all the collectors will fill

completely before any one drains, and all the

water from the collectors can drain completely

to the tank. 95/5 solder is recommenced for all

joints on the collectors.

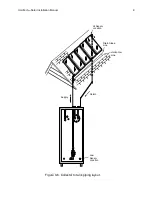

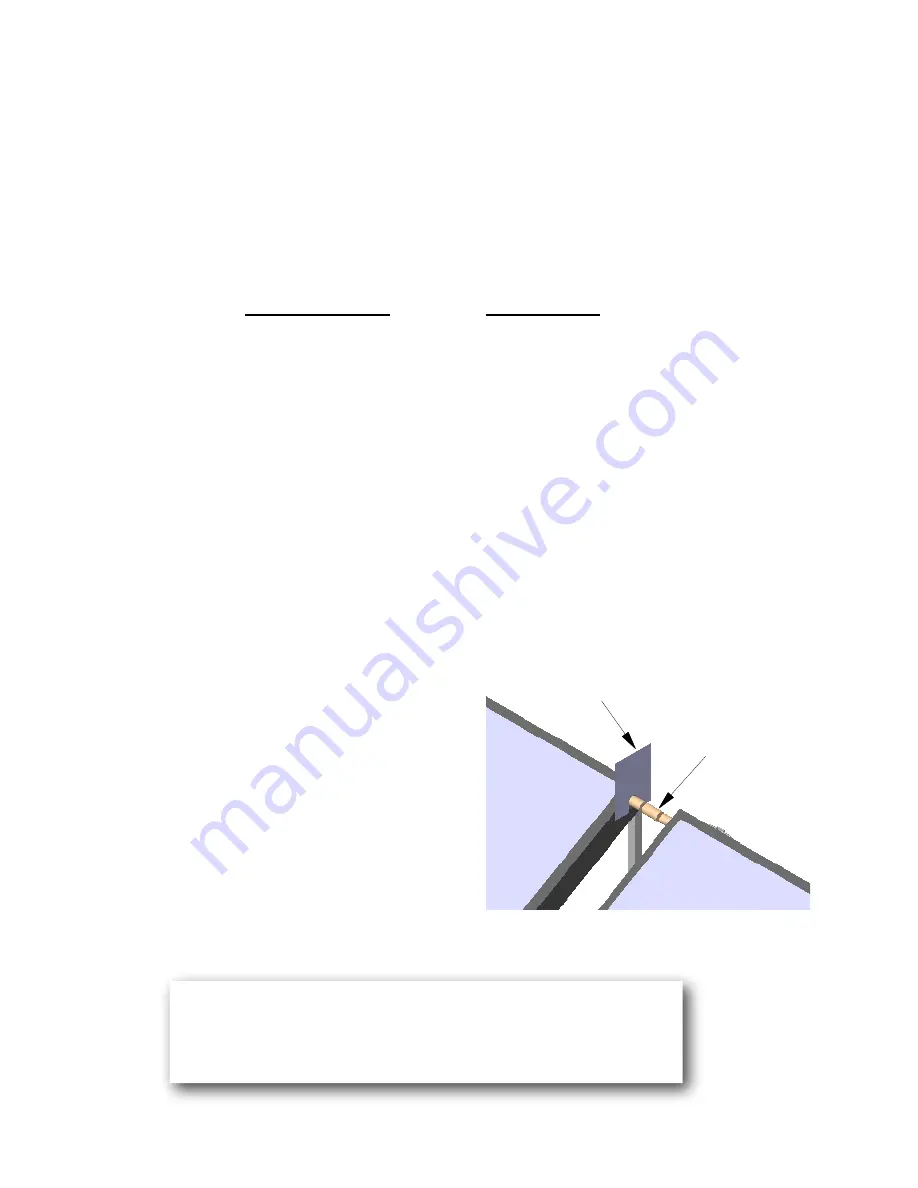

A good technique for soldering the collector

manifolds is to use a solder shield, or flame

shield, to protect the grommet from excess

heat. See fig. 3.7. The shield is a piece of

sheet metal with a slot cut out to go over the

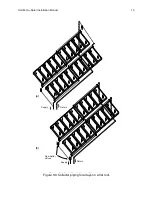

pipe. Top and bottom collector headers are

joined directly together to form a common

manifold for all collectors in a bank.

HoloTech

tm

Solar Installation Manual

10

1" coupling

solder shield

95/5 solder

Figure 3.7 Solder shield for joining

collectors.

NOTE

The collector header pipes must be completely cleaned of all

black plating before soldering! Solder will not stick to black

plating!