BA_PH_546-100_EN_06-22.docx

40

11.5

Calibrating the Table Height (

“

Setup

”

Menu)

The position controller makes it easy to calibrate the height of the thicknessing table.

For this purpose, you must first switch from normal positioning mode to the setup menu.

•

Press the

“

Home

”

button to switch to the main menu.

•

Then press the

“

Setup

”

button to enter the setup menu:

→

An alphanumeric keyboard appears with a password request.

Enter the password

7550

and confirm with

“

ENT

“ (Enter).

→

If the password has been entered correctly, the button

“

Calibrate

“

appears on the screen.

•

Now press the

“

Calibrate

“ button to enter the calibration menu

:

→

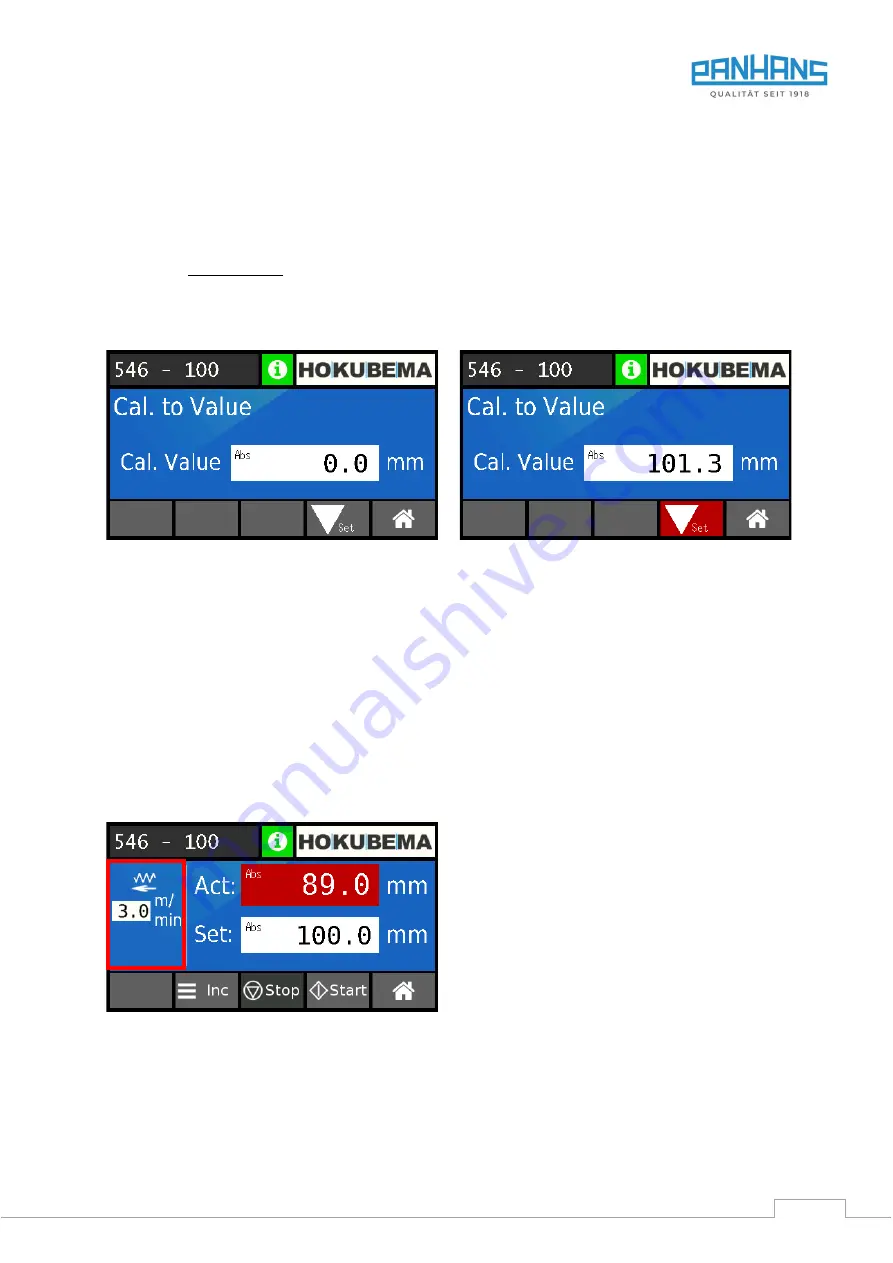

The calibration screen appears (see

Figure 42: Calibrate table height

Figure 43: Input of the reference value

•

Now use a test workpiece that has already been dressed and set the table to any height that is suitable for a

thickness planing test run with the selected test workpiece.

•

Start the thickness planing test run.

•

Measure the machined test workpiece with a suitable measuring device (vernier caliper recommended!)

•

Enter the measured value (z. B.

101.3

mm) into the

“

Cal. Value

”

field (see

→

The "Set" button in the bottom line of the screen is highlighted in red.

•

Then press the

“

Set

”

button:

→

The table is automatically calibrated to the reference dimension

•

Finally, press “

Home

” to return to the main menu

.

11.6

Feed Rate Visualisation (Option)

Figure 44: Feed rate visualisation

On machines with infinitely variable feed rate (option

see section

16.1.3), the current feed rate is visual-

ised on the left-hand side of the screen, as shown in

the figure on the left.

Note:

This function is unavailable on machines with

two-stage standard feed.