Attention:

The plug must be accessible even after the installation of the

appliance in case there is a need to disconnect it. If not

possible, connect appliance to a double-pole switching device

with contact separation of at least 3 mm placed in an

accessible position even after installation

.

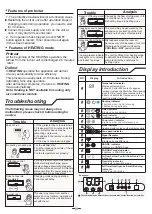

Cable Specifications for Inverter appliance

NOTE:

NOTE:

1.K* means the

this model comes from indoor unit.

2.K** indicates indoor power supply unit model with power line and

plug.

3.For 14K*~18K* models under Tropical(T3) Climate condition, the

normal cross-sectionl area of Power cord and Power connecting

2

cord is 2.5mm ×4

power supply of

.

Capacity

(Btu/h)

5K~13K

H07RN-F

IS:9968

H05VV-F

IS:694

IS:694

IS:694

5K*~

K*

13

Power connecting cord

Power cord

Type

Type

Normal cross

- sectional area

Normal cross

- sectional area

0.75~1.5

2

mm X4

0.75~1.5

2

mm X4

0.75~1.5

X3

2

mm

2

0.75~1.5

mm X3

H07RN-F

H07RN-F

H05VV-F

H05VV-F

2

2.5mm X3

2

2.5mm X3

2

1.5mm X3

2

2.5mm X4

2

2.5mm X4

2

1.5mm X4

2

1.0mm X4

H07RN-F

2

2.5mm X3

H07RN-F

2

2.5mm X3

H07RN-F

2

2.5mm X5

H07RN-F

H07RN-F

IS:9968

IS:9968

2

1.5/2.5mm X3

2

1.5/2.5mm X3

H05VV-F

2

1.5/2.5mm X4

2

1.5/2.5mm X4

21K*~30K*

21K**~24K**

21K~36K

H07RN-F

H05RN-F

2

0.75mm X4

0.75~1.5

X3

2

mm

14K*~

K*

18

H07RN-F

2

1.5mm X3

H07RN-F

2

1.5mm X5

H07RN-F

H07RN-F

0.75~1.5

2

mm X5

0.75~1.5

X3

2

mm

14K~18K

H07RN-F

2

1.5mm X3

H05RN-F

2

0.75mm X4

2

0.75mm X4

H05RN-F

2

2.5mm X3

H07RN-F

Cable Specifications for ON-OFF appliance

2

2

The cord may be different from the list above. It may be used as

the next list. And it can be larger.0-6A, use 0.75mm or 18AWG.

0-10A, use 1mm or 16AWG. 0-16A, use 1.5mm or 14AWG 0-20A,

use 2.5mm or 14AWG. 0-25A, use 2.5mm or 12AWG. 0-32A,

use 4mm

2

2

2

2

2

2

Capacity

(Btu/h)

To indoor

H07RN-F

Power connecting cord

Power cord

Type

Type

Type

Normal cross

- sectional area

Main

power

supply

Normal cross

- sectional area

Normal cross

- sectional area

Power connecting cord1

2

2.5mm X3

To indoor

To outdoor

2

1.5~2.5mm X3

5K~13K

H05VV-F

2

0.75~1.5mm X3

H05VV-F

H05RN-F

H05RN-F

H05RN-F

2

1.5~2.5mm X3

2

0.75mm X2

(Heat-pump)

2

0.75mm X2

(Heat-pump)

2

0.75mm X3

(Heat-pump)

H07RN-F

H05RN-F

H07RN-F

2

0.75~1.0mm X3

2

1.5mm X3

2

1.0mm X3

2

1.0mm X4Cooling only

To indoor

18K~30K

2

1.5~2.5mm X3

H05VV-F

2

1.5~2.5mm X4

H07RN-F

H07RN-F 2.5~

X3

2

4.0mm

To outdoor

24K~36K

H05RN-F

H07RN-F

14K~24K

H05RN-F

2

0.75mm X2

(Heat-pump&Optional)

18K~30K

H07RN-F

1.5

X5

2

mm

To outdoor

H05RN-F

2

0.75mm X4

24K~36K

H05RN-F

2

0.75mm X2

(Heat-pump)

H05RN-F

H07RN-F

2

1.0mm X4

2

0.75mm X4

H05RN-F

2

0.75mm X2

(Heat-pump&Optional)

Wiring diagram

Warning:

Before obtaining access to terminals, all supply

circuits must be disconnected.

Make sure that the color of the wires in the outdoor

unit and terminal No. are the same as those of the

indoor unit, the details please refer to the wiring

diagram which is near the terminal inside the unit

.

Outdoor unit installation

1. Install Drain Port and Drain Hose (for heat-pump

model only)

Drain hose

(prepared by user)

Washer

Drain port

Rubber pad (optional)

Place under the leg pedestal

The condensate drains

from the outdoor unit when

the unit operates in heating

mode. In order not to

disturb your neighbor and

protect the environment, install

a drain port and a drain hose to direct

the condensate water. Just install the drain port and

rubber washer to the chassis of the outdoor unit,

then connect a drain hose to the port as the right

figure demonstrates.

2. Install and Fix Outdoor Unit

Fix with bolts and nuts tightly on a flat and strong

floor. If installed on the wall or roof, make sure to fix

the supporter well to prevent it from shaking due to

serious vibration or strong wind.

3. Outdoor Unit Piping Connection

Remove the valve caps from the 2-way and 3-way

valve.

Connect the pipes to the 2-way and 3-way valves

separately according to the required torque.

4. Outdoor Unit Cable Connection (see previous

page)

Air purging

The air which contains moisture remaining in the

refrigeration cycle may cause a malfunction on the

compressor. After connecting the indoor and outdoor

units, release air and moisture from the refrigerant

cycle using a vacuum pump, as shown below.

Note: To protect the environment, be sure not to discharge

the refrigerant to the air directly.

Refrigerant flow direction

2-way valve

(6) Open 1/4 turn

valve cap

(1) Turn

(8) Tighten

(2) Turn

3-way valve

(8) Tighten

(1) Turn

(7) Turn to fully open the

valve

(7) Turn to fully open the valve

(8) Tighten

3-way valve diagram

connect to indoor unit

open position

spindle

service port cap

Service

port

Connect to outdoor unit

Valve core

needle

indoor unit

Valve cap

Vacuum pump

16