56

9. WHEN IT IS NOT USED FOR LONG TIME

Be sure to follow the measures below if the compressor is stored or stopped by reason of

Power supply problem for a long time. (Follow

○

marked items)

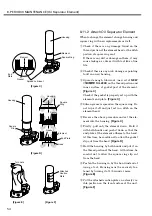

Procedure for Long Time Stoppage and Storing

Measures

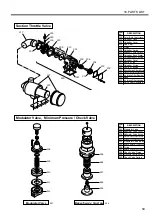

Open the 1/2-inch stop valve at the end

of the oil-draining pipe that extends

from the oil case and thus drain the con-

densate. Close the 1/2-inch stop valve

when the oil comes out instead of the

condensate.

Measure insulation resistance between

each phase of the motor.

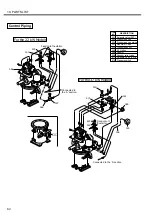

Check is stain is found to M-sheave

and V-Pulley.

Rotate the V-Pulley manually to check

compressor (screw block)’s rotation.

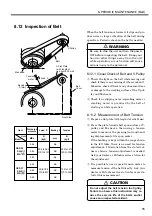

Check the V-belt.

Replace the lubricant.

Check power cables and terminals for

deterioration or rusting.

○

○

○

○

○

○

○

To recover its insulation capacity,

or replace the motor. (NOTE)

Remove rusting with finer sand

paper from the slot (NOTE).

Disassemble and check the com-

pressor (screw block) (NOTE).

Replace V-belt (NOTE).

Replace it with new one.

(After stop, take out condensate one day later and do

not drain the lubricant.)

More than 1M ohm

at DC 500V Mega.

No rusting in the

slots.

Smooth rotation.

Replace in whole.

No deterioration nor

rusting.

(NOTE) Ask your dealer or Hitachi Service Station for information.

Criteria

Measures If Criteria Is Not Filled

3 to 6 months 6 to 12 months

Storage Period

Check it for its tension

(Refer to the mainte-

nance standards) and

no crack from appear-

a n c e , a n d e n o u g h

elastic force is kept.

Special

anti-rusting

measures

required.

Ask your

dealer or

Hitachi

Service

Station for

information.

Measures

Before

Storing

●

The compressor air end (screw block) can have rustings if no anti-rusting measure

(Measures before storing, sealing) are done to it. If the unit is restarted, this may

result breakage in Locks or Bearings of the compressor.

●

If necessary measures are failed when to restart the unit, it may result damage to

the Locks or Bearing, burning in the motor, excessive wear of M-sheave and V-

Pulley, breakage of V-Belt to the compressor.

●

If lubricant has not been replaced when necessary or if enough flashing has not

been done to the unit, the lubricant deteriorates earlier than usual and this may

result clogging in Lock and Oil Cooler to the compressor.

CAUTION

Measures

Before

Restarting

Содержание HISCREW 2000 Series

Страница 70: ...68 This page is intentionally blank ...