27

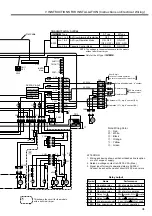

5. TROUBLESHOOTING [A List of SHUTDOWNS Not Displayed on Instrument Panel]

Readjust

Replace

Cleaning and refastening of Plumbing Equipments

Replace

Replace

Resetting

Replace with the appropriate one

Replace it with genuine synthetic oil (flashing inside is required.)

Check of Drain Suction Port and drainage

Flushing at Lubricant change

Disassemble/Repair

Replace

Refastening

Add some mortar to settle the foundation levelly

Adjust Belt Tension or replace it

Refastening

Add some mortar to settle the foundation levelly

Clean Fins

Clean

Clean drain discharge system then drain from under air cooler.

Adjust hot gas bypass valve to be 0.41 MPa or more.

Replace bypass valve if unadjustable.

Repair then fill refrigerant.

Keep ambient temperature below 40

°

C.

Clean cooler and replace fan.

Wash cycle then replace evaporator.

Adjust bypass valve to be the specified pressure.

Replace if unadjustable.

Capacity Control

malfunction

Lubricant

deterioration

too early

Strange noise from

the Main Body

Other unfamiliar

noises

Strange noise from Belt

Excessive Vibration

SYMPTOMS AND TROUBLES

POSSIBLE CAUSES

REMARKS

SOLUTIONS

*

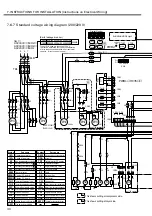

Only for the 37 kW models.

**

Only if you installed an ammeter on the power supply.

1. Running the unit with deteriorated lubricant unchanged or in a very hot condition brings the lubricant

ignites and this may cause serious accident.

Keep the lubricant well controlled (See pages 18 through 19).

2. Do not operate the unit without protective equipment. In case of SHUTDOWN, read this section “5.

TROUBLESHOOTING” to remove the cause. If the cause is unknown, inform and ask your dealer or

Hitachi Service Station.

WARNING

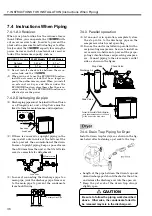

●

Running the unit with its loose belt brings not only lowered discharge air capacity due to its slipping,

but also life of belt shortened. If belt is broken during the operation, the lubricant blows out of the

Suction Throttle Valve. Be sure to carry out your constant check on belt.

●

If the unit stops due to the function of Temperature Relay, check leakage in the mechanical seal and

replace it if lubricant leak is found there.

CAUTION

Adjustment failure of Modulator Valve

Start Solenoid Valve* and/or Blow-off Solenoid Valve: Failed

Air-leak or clogging in plumbing system

Cap Seal damaged

Suction Throttle Valve’s rubber seat damaged or deformed

Inappropriate pressure setting

Use of other than genuine synthetic oil (NEW

A

OIL 2000)

Ambient Air Temperature too high

Water in the system

Deteriorated Lubricant still left

Compressor grips Foreign Particle

Inappropriate friction or damage of Bearing

Loose Bolts or Screws

Fault Installation

Belt slipping

Loose Bolts or Screws

Fault Installation

Unbalance of the unit due to Cooling Fan contamination

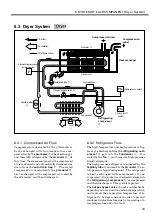

Drain trap clogging

Drain discharge system clogging

Air cooler frozen

Refrigerant leak

High intake air temperature

Noncondensing gas mixed in cycle

Hot gas bypass valve fault

Dryer fault

Refrigerant

pressure is low

but waterdrops

gather at outlet.

Refrigerant

pressure is high

and waterdrops

gather at outlet.

Содержание HISCREW 2000 Series

Страница 70: ...68 This page is intentionally blank ...