10

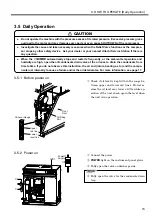

q

Be sure the power is OFF.

w

Be sure that grounding is firmly connected.

e

Be sure the discharge pressure gauge indicates 0.

r

Detach the door (for the 22 kW models) or the

front enclosure panel (for the 37 kW models)

and remove the starter/control box cover.

Make sure that the DIP switches

SW1

and

SW2

on the printed circuit board are correctly

set. (

☞

pp. 12-14)

t

Check if oil level is kept around the upper red

line on the oil level gauge.

(Oil level lowers while operation)

3.3 Initial Start-Up

3. HOW TO OPERATE [Initial Start-Up]

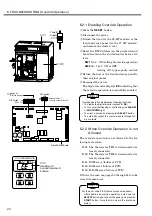

3.3.1 Before power on

Every button such as START, STOP and RESET will

not function unless the switch held down more than 0.3

second.

After the installation, or after long unused time (over a week),

run the machine by way of initial start-up.

Capacity control of S-type is preset to

I

-type control,

and M-type is to P-type (AUTO) control.

Refer to page 12 for the setting of control function when

the control type is changed.

Compressor shifts repeatedly between full-load and no-

load operation within the range of its discharge pres-

sure between 0.69 MPa and 0.59 MPa.

Before turn the power ON, make sure if

z

installation,

x

piping and

c

electrical wir-

ing have been properly completed.

CAUTION

Oil has been filled in the oil case by the

factory before delibery.

CAUTION

q

Connect the power.

w

See if

POWER

light glows on the compressor’s

instrument panel.

e

Digital monitor displays run hour in 10 hours

as a unit.

r

Fully open the valve on discharge side.

For safety, the unit will not operate for 5 seconds after

the power is ON, even START button is pressed.

3.3.2 Power on

IMPORTANT

IMPORTANT

IMPORTANT

⑤

②

④

③

①

Power

Supply

③ ②

①

④

Power

Supply

Содержание HISCREW 2000 Series

Страница 70: ...68 This page is intentionally blank ...