-5-

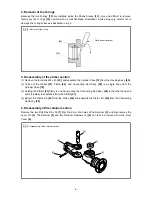

Fig. 6 • Mounting the striker

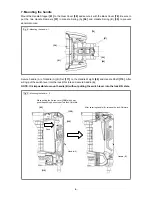

Fig. 7 • Mounting oil seal (A)

5. Mounting the striker

The striker can be mounted in either of the following two ways.

• Mount the Connecting Rod Ass’y

[28]

to the Crank Shaft

[48]

inside the Housing Ass’y

[49]

. Mount the

Piston

[26]

and apply grease for hammer. hammer drill (Code No. 980927) to the inside and outside of

the Striker

[21]

. Turn the Crank Shaft

[48]

and move the Connecting Rod Ass’y

[28]

all the way inside the

Housing Ass’y

[49]

. Then mount the Striker

[21]

.

• Mount the Piston

[26]

onto the Connecting Rod Ass’y

[28]

. Apply grease for hammer. hammer drill

(Code No. 980927) to the inside and outside of the Striker

[21]

. Mount the Striker

[21]

.

Either of the above two ways requires a pressing force of more than 30 kg.

When a "hissing" sound is heard, the Piston

[26]

is properly inserted in the Striker

[21]

.

(The "hissing" is the sound of the compressed air escaping from the Striker

[21]

when the Piston

[26]

reaches the respiratory hole in the Striker

[21]

.)

6. Mounting oil seal (A)

When mounting Oil Seal (A)

[27]

on the Piston

[26]

,

ensure that the lip portion of Oil Seal (A)

[27]

is

directed toward the rear surface of the Piston

[26]

as

illustrated in Fig. 7. Before mounting, thoroughly coat

Oil Seal (A)

[27]

and O-ring (A)

[22]

with grease for

hammer. hammer drill (Code No. 980927) and

carefully ensure they are not damaged.

[21]

(Grooved for identification)

Piston length 48 mm

[49]

[48]

Press.

[28]

Press.

Respiratory holes

[26]

Respiratory holes

[22]

[27]

Lip

[26]