-5-

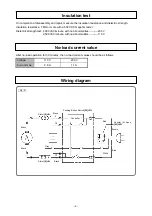

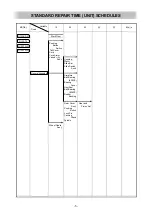

MODEL

Variable

Fixed

10 20 30 40 50

60

min.

G 10SS2(S)

G 12STX

G 12STA(S)

G 13STA(S)

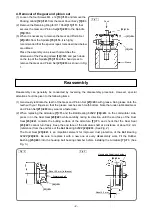

General Assembly

Housing

Stator

Slide Bar

Slide Switch

Knob

Armature

Ball Bearing

(608SS)

Bearing

Cover

Dust Seal

Ball Bearing

(626ZZ)

Rubber

Bushing

Gear Cover

Ass’y

Pushing

Button

Lock Pin

Packing

Gland

Spindle

Gear and

Pinion Set

Work Flow

Pushing

Button

Switch

Tail Cover

Cord

Cord Armor

Varistor (A)

Ass’y

Wheel Guard

Ass'y

STANDARD REPAIR TIME (UNIT) SCHEDULES