-3-

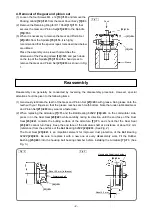

Fig. 4

(3) Before inserting the Stator

[9]<9>

into the Housing

[26]<25>

, correctly connect the internal wires of the

Stator

[9]<9>

to each part without entangling as shown in Fig. 4.

NOTE: • Be careful not to put the internal wire of the Carbon Brush [27]<26> between the

Housing [26]<25> and the internal wires of the Stator [9]<9> when connecting the

internal wires of the Stator [9]<9> or when connecting the Carbon Brush [27]<26>.

• The internal wire (single wire) of the Stator [9]<9> is covered with a heat-shrinkable

tube. Do not forcefully bend the internal wire of the Stator [9]<9> repeatedly and do

not peel off the heat-shrinkable tube when mounting the Stator [9]<9> to the Housing

[26]<25>. Otherwise, the internal wire may be disconnected.

• Do not forcefully bend the stator terminal when inserting the stator terminal into the

Pushing Button Switch [32]<31> and the tab terminal. Otherwise, the stator terminal

may be broken.

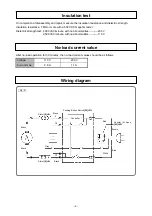

(1) When replacing the Gear Cover Ass’y

[3]<3>

, lubricate the metal with the following mixed oil.

Mixed oil: Mixture of Hitachi power tool grease No. 2 (Unilube No. 00) and turbine oil

• Mixture ratio: 1:1 (weight ratio)

• Volume: 0.5 cc

(2) Generously rub 10 g of Shell GADUSS2V1003 grease onto the gear and pinion of the Gear Cover

Ass'y

[3]<3>

.

• Seal Lock Screw (W/Washer) M4 x 12

[13]<13>

-------- 1.8 ± 0.5 N•m (18 ± 4 kgf•cm, 1.3 ± 0.3 ft-lbs.)

• Tapping Screw (W/Flange) D4

[41][36]<40><35>

------ 2.0 ± 0.5 N•m (20 ± 5 kgf•cm, 1.5 ± 0.4 ft-lbs.)

• Machine Screw (W/Sp. Washer) M5 x 16

[16]<16>

---- 3.4 ± 0.7 N•m (35 ± 7 kgf•cm, 2.5 ± 0.5 ft-lbs.)

• Special Nut M6

[4]<4>

----------------------------------------- 4.9 ± 1.0 N•m (50 ± 10 kgf•cm, 3.6 ± 0.7 ft-lbs.)

• Tapping Screw D3 x 8

[29]<28>

----------------------------- 0.6 ± 0.1 N•m (6.2 ± 1.2 kgf•cm, 0.4 ± 0.07 ft-lbs.)

Lubrication point and type of lubricant

Tightening torque

Connect the internal wire to the

Pushing Button Switch

[32]<31>

.

White

White

Connect the internal wires to

the Tab Terminal

[28]<27>

.

Connect the internal wire to the

Pushing Button Switch

[32]<31>

.

[26]<25>

[9]<9>