-2-

Fig. 1

4. Removal of the gear and pinion set

(1) Loosen the four Screws M4 x 12

[13]<13>

and remove the

Packing Gland

[12]<12>

from the Gear Cover Ass'y

[3]<3>

.

(2) Remove the Retaining Ring for D11 Shaft

[11]<11>

that

secures the Gear and Pinion Set

[21]<20>

to the Spindle

[15]<15>

.

(3) When it is necessary to remove the Gear and Pinion Set

[21]<20>

from the Spindle

[15]<15>

, it is highly

recommended that the special repair tools described below

are utilized.

Place the assembly on a sleeve that matches the

dimension of the Packing Gland

[12]<12>

and push down

on the top of the Spindle

[15]<15>

with a hand press to

remove the Gear and Pinion Set

[21]<20>

as shown in Fig.

1.

Reassembly can generally be conducted by reversing the disassembly procedure. However, special

attention should be given to the following items.

(1) Generously lubricate the teeth of the Gear and Pinion Set

[21]<20>

with grease. Rub grease onto the

teeth with your fingers so that the grease reaches each tooth bottom. Note that under-lubricated Gear

and Pinion Set

[21]<20>

may wear at a faster rate.

(2) When replacing the Armature

[7]<7>

and the Ball Bearing 626ZZ

[24]<23>

on the commutator side,

press in on the Dust Seal

[23]<22>

while carefully noting its direction until the end face of the Dust

Seal

[23]<22>

contacts the butting surface of the Armature

[7]<7>

, and check that the Dust Seal

[23]<22>

cannot turn freely. Keep the end face of the armature shaft at a distance of about 0.2 mm

(reference) from the end face of the Ball Bearing 626ZZ

[24]<23>

. (See Fig. 2.)

The Dust Seal

[23]<22>

is an important element for improved dust protection of the Ball Bearing

626ZZ

[24]<23>

. Be sure to replace it

with a new one at every disassembly work. Fit the Rubber

Bushing

[25]<24>

into the housing ball bearing chamber before installing the Armature

[7]<7>

. (See

Fig. 3.)

Reassembly

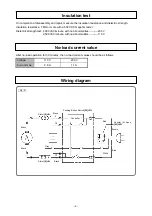

Fig. 2

Fig. 3

Push.

[15]<15>

[21]<20>

[12]<12>

Sleeve

About 0.2 mm (reference)

Housing ball bearing chamber

[25]<24>

About 4.5 mm

Armature shaft

[24]<23>

[23]<22>