-6-

III

II

0

I

2.0 mm (5/64”)

1.2 mm

(3/64”)

0.6 mm (1/32”)

20 mm (3/4

”)

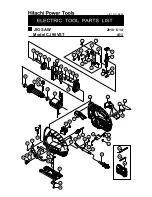

1. Blade Movement

In the Model CJ 90VST, the orbital mechanism moves the blade up and down, and back and forward. The

amount of fore-and-aft blade movement can be adjusted by simply switching the change knob to any of the

four settings. The table below shows the modeled orbits of blade movement at each orbital position

(change knob position).

III

II

I

0

Orbit

al po

sition

Blade ed

ge mo

vem

ent

Perpendicular

movement only

2. Orbital Position Selection

Selecting the most appropriate orbital position for each cutting job is essential to achieve the best possible

cutting efficiency. However, as the best orbital position depends on workpiece hardness and thickness, the

desired finish of the cut surface, and other factors, setting a single, simple standard for selecting the best

orbital position is not practical. Table 1 below can be used as a general guide for the appropriate selection

of orbital position based on various factors.

Table 1 General guide for appropriate selection of orbital position

Orbital position

Factor

III II I 0

Material hardness

Soft material

Hard material

Material thickness

Thick

Thin

Cutting speed

Faster cutting

Slower cutting

Straight cutting or

curved cutting

Straight cutting

Curved cutting

Surface finish

Rough finish acceptable

(splintering, chipping acceptable)

Fine finish

Material stability

Unstable

Very stable

* Set the orbital position to "0" independently of the cutting speed when cutting a small arc or curved line by

using a guide (sold separately).

ORBITAL MECHANISM AND BLADE