-275-

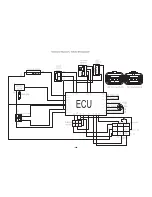

ENGINE MANAGEMENT SYSTEM

- 275 -

not to injure the electrode or the

insulator tip

DO

:

Regap spark plugs to the exact

measurement specified by the engine

-Too wide a gap could cause the plug to

misfire(higher required ignition voltage).

manufacturer to keep the best fuel economy and

proper engine performance

- Use round wire-type gauge for an accurate

measure of gap on all used spark plugs

- when gapping a spark plug only the side

electrode is moved. The center electrode must

not be moved

-Too narrow of a gap could affect idle stability

-A flat gauge can’t accurately measure the spark

plug on used plugs

DO

:

When replacing spark plugs with new ones,

always use equivalent plugs with same heat

range, thread, size, etc….

-Higher heat range plug(hotter plug) could lead

to pre-ignition & possible piston damage

-Lower heat range (colder plug) could lead to

cold fouling & emission problem

DO

:

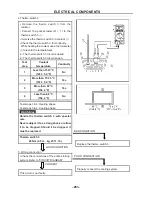

For installing spark plugs follow the following

steps:

1- make sure the cylinder head threads and

spark plug threads are clean. Make sure the

spark plug thread is free of dings and burrs. If

necessary, use a thread chaser and seat

cleaning tool.

2- Make sure the spark plug gasket seat is

clean, then thread the gasket to fit flush

against the gasket seat. Tapered seat plugs

do not require gaskets

3- Screw the spark plugs finger-tight into the

cylinder head. Then, use a torque wrench to

tighten spark plugs following manufacturer’s

recommendation).

Torque is different for various plug type & cylinder

head material

-If the thread is damage, it prevents a good heat

transform from the shell to the cylinder head

-Do not use any type of anti-seize compound on

spark plug threads. Doing this will decrease the

amount of friction between the threads. The

result of the lowered friction is that when the

spark plug is torqued to the proper specification,

the spark plug is turned too far into the cylinder

head. This increases the likelihood of pulling or

stripping the threads in the cylinder head

-Over-tightening of a spark plug can cause

stretching of the spark plug shell and could

allow blowby to pass thru the gasket seal

between the shell and insulator. Over-tightening

also results in extremely difficult removal

Fuel Pump Module

1

.

Description and Working Principle

Fuel Pump Module supplies fuel to engine at system pressure. Fuel Pump Module is

mounted to fuel tank at bottom and supplies fuel to engine through hoses.

Fuel Pump module consists of Fuel Pump to generate the fuel flow and pressure regulator to

regulate the fuel pressure.

Fuel Pump

When power is supplied to fuel pump, motor in pump assembly rotates the impeller. Impeller in

turn draws the fuel from strainer and pumps the flow to generate the system pressure.

Содержание HS200UTV

Страница 3: ......

Страница 15: ......

Страница 94: ... 79 SPECIFICATIONS 79 HYDROGRAPHIC CHART Hydrographic chart Pressure ...

Страница 95: ... 80 SPECIFICATIONS 80 LUBRICATION OIL WAY LUBRICATION OIL WAY Pressure splashing oil ...

Страница 248: ... 233 CHASSIS 233 Fuel tank cap Remove the fuel tank cap by turning it counterclockwise ...

Страница 263: ... 248 ...

Страница 304: ... 289 ...

Страница 305: ... 290 ...

Страница 306: ... 291 ...

Страница 307: ... 292 ...

Страница 308: ... 293 ...

Страница 309: ... 294 ...

Страница 310: ... 295 ...

Страница 311: ... 296 ...

Страница 312: ...TM HISUN MOTORS 310 East University Dr McKinney Texas 75069 PH 972 446 0760 TF 877 838 6188 hisunmotors com ...